Optical fibers are successfully

used in various areas, such as

cardiology and so much more!

Optical fibers are successfully used in various areas of medicine, including urology, general surgery, ophthalmology, cardiology, endoscopy, dentistry and medical sensing [1 – 4]. Prior to use inside a human body the fiber must be sterilized to ensure it is free of microorganisms such as fungi, bacteria, and virus or spore forms.Sterilization can generally be defined as any process that effectively kills or eliminates all microorganisms from a surface, contained in a fluid, equipment, food, medication or biological culture medium [5]. Many types of physical or chemical treatments are known as effective sterilization techniques. Roughly, the methodologies can be subdivided into three groups: (i) use of elevated temperatures, (ii) chemical treatment, and (iii) exposure to radiation. The first group includes flaming, exposures to dry heat and hot steam (autoclaving) and boiling in water. Chemicals such as ethylene oxide (EtO), formaldehyde, ozone, hydrogen peroxide, phthalaldehyde and peracetic acid in the gas phase and/or solutions are used for chemical sterilization. Finally, microorganisms can be effectively killed by UV light, X-rays, gamma- and e-beam radiation.

OFS investigated the effects of different sterilization methods on performance of several optical fibers designed for medical applications. Three common sterilization methods were selected: (i) steam sterilization (autoclaving), (ii) treatment with ethylene oxide and (iii) gamma radiation. The fibers under study were employed with different coatings: dual acrylate, hard polymer clad, silicone and polyimide.

In an autoclave, the fibers are exposed to relatively high temperature and highly concentrated water vapor. This combination may cause cracking of polymer coatings and/or deterioration of the glass cladding surface. Both factors may result in strength degradation of the fiber, which changes are typically cumulative [12]. In most medical applications, the maximum number of autoclave cycles does not exceed 20, so in our study the maximum number of cycles was selected to be 20.

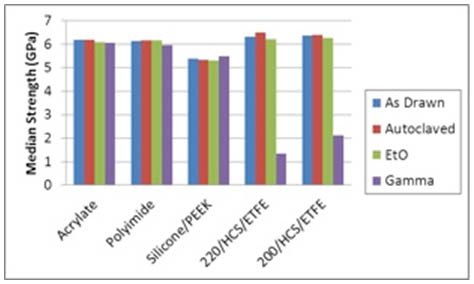

EtO treatment conditions applied in this study (0.5 atmospheres of 100% EtO, 60°C, 7.5 hours dwell time) were same as commonly used for various medical devices. It can be seen from Figure 4.2.1 and Table 4.1.1 that exposure to ethylene oxide did not produce any effects on the fiber strength. It follows that EtO molecules did not cause any chemical degradation of the silica and polymer coatings.

Gamma radiation dose applied in this study (40 – 50 kGy) was typical for medical sterilization. It is known that 25 kGy dose is 40% above the minimum to kill the most resistant microorganisms [13]. Whereas a minimum dose of 25 kGy is desired for microbial control, the actual applied dose is often in the 25 – 50 kGy range. It can be seen from Figure 4.2.1 and Table 4.1.1 that exposure to gamma radiation lead to a significant strength degradation of fibers with HCS®/ETFE coating/buffer layers. At the same time, mechanical strength of fibers with acrylate, polyimide and silicone/PEEK coatings was not affected.

Figure 4.2.1. Effects of sterilization conditions on median strength (sm) of optical fibers.

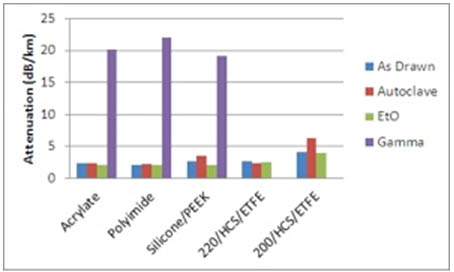

In more details, effects of sterilization on the fibers can be followed from the attenuation spectra. Figure 4.3.2 shows the data obtained for the fiber with dual acrylate coating. It can be seen that the spectra of the as-drawn, autoclaved and EtO treated fibers are nearly identical. The gamma radiation resulted in additional losses which gradually increase at shorter wavelengths.

Figure 4.3.2. Attenuation at 850 nm (OTDR data) for as-drawn and sterilized optical fibers.

It has been found that EtO treatment did not cause any harm to mechanical and optical properties of the fibers. Multiple autoclaving cycles caused minor influence on the fiber strength. The only found effect was a gentle decrease of nd observed for the fiber with dual acrylate coating. For most fibers, the attenuation was not or very weakly affected by the autoclaving. The only exception was the polymer-cladded fiber where O-H absorption peaks developed in the spectra upon the autoclaving treatment.

In contrast, gamma radiation was found to strongly affect the fiber attenuation. Furthermore, mechanical strength of fibers with fluorine-containing coatings rapidly degraded upon the exposure to gamma radiation. It follows that gamma radiation should be generally avoided for optical fibers. Still moderate radiation doses (≤25 kGy) can be applied to fibers with non-fluorinated coatings, assuming that the fibers are utilized at wavelengths above 1000 nm.

Disclaimer. Some of the results herein are based on the latest techniques of accelerated testing. Although as such, they may provide an indication of the useful service performance of materials, they do not constitute or imply any warrantee on behalf of OFS. No warrantees other than OFS’ normal contractual warrantees should be inferred.

Acknowledgements. The authors would like to thank our colleagues William P. Smith, Paula Fournier and Tomas W. McNally and Glenn Smart for their help at different stages of the work.

References

[1] M. Ben-David, I. Gannot, Optical fibers for biomedical applications, in Specialty optical fiber handbook, Elsevier, Amsterdam, P. 699 – 733 (2007).

[2] G. T. Petrovski , S. V. Danilov, G. Ya. Konaeva, L. S. Trofimova, and V. Kh. Yagmurov, Flexible illuminator fiber bundles for medical instrumentation, J. Opt. Technol. V. 70, P. 114 – 119 (2003).

[3] R. George, L. J. Walsh, Performance assessment of novel side firing flexible optical fibers for dental applications, Lasers in Surgery and Medicine, V. 41, P. 214 – 221 (2009).

[4] M. G. Shim, B. C. Wilson, E. Marple, M. Wach, Study of fiber-optic probes for in vivo medical Raman spectroscopy, Appl. Spectrosc., V. 53, P. 619 – 627 (1999).

[5] M. Silindir, A. Y. Ozer, Sterilization methods and comparison of e-beam sterilization with gamma radiation sterilization, FABAD J. Pharm. Sci., V. 34, P. 43 – 53 (2009).

[12] A. A. Stolov, B. E. Slyman, D. A. Simoff, A. S. Hokansson, R. S. Allen, J. P. Earnhardt, Optical fibers for polyimide coatings for medical applications, Proc. SPIE, V. 8215, P. 82150B (2012).

[13] A. Tallentire, The spectrum of microbial radiation sensitivity, Radiat. Phys. Chem. V. 15, P. 83 – 89 (1980).

Written by,

Steve Allen