Optical fiber shape sensing is a form of distributed sensing that uses scattered signals from optical fibers to ascertain local curvature and twist and thus the shape of a given structure. The twist and bend information is recorded by an interrogator which then reconstructs the fiber shape through a series of geometric formulations. Although shape sensing is aimed towards the medical market, it can be utilized in other markets as well: energy, defense, aerospace, structural health monitoring and other smart structures.

The OFS shape sensor module consists of a length (>1m) of twisted multicore optical fiber with discrete or quasi continuous fiber Bragg gratings inscribed along its length. A typical shape sensor optical fiber has a 200 μm coated diameter, a twist of 50 turns per meter and grating reflectivities greater than 0.01% per cm of array, suitable for high efficiency scatter measurements over many meters of fiber.

The fiber used in shape sensing is coated with a UV transparent coating that ensures fiber strength while allowing grating inscription using standard methods. Importantly, the core positions have minimal variation in effective index and positioning. These tolerances improve the accuracy of the resulting shape sensor and make the Bragg resonance of the gratings highly repeatable between cores.

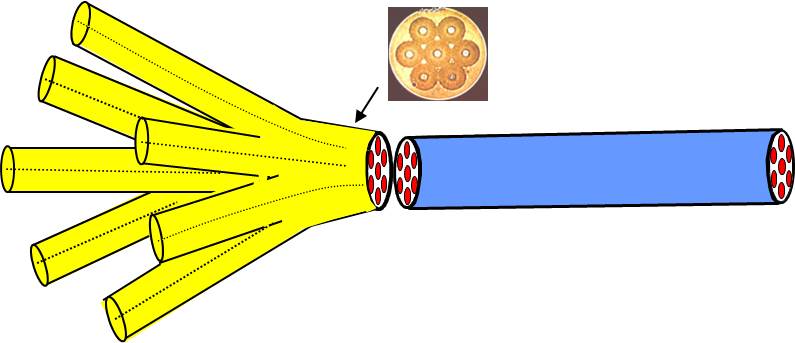

A critical component for a multicore optical fiber shape sensing system is a fanout that allows efficient, low loss connection between interrogator components and the multicore shape sensor assembly. OFS realizes such devices with tapered optical fiber bundle technology. The tapered fiber bundle (TFB) technology breaks out the seven cores of the fiber into separate, single core fibers. In figure one you can see the transformation of one multicore fiber to seven separate cores. From this point, the seven fibers are each connected to the interrogator to extract shape information.

The axial twist created during the fiber draw process is critical to making an effective multicore optical fiber sensor. The optical fiber is comprised of seven cores. The six outer cores are twisted. They form a helix around the center core, and are sensitive to bend and twist while the center core acts as a reference along the length of the fiber. A fiber twist strains all outer cores the same way, whereas a fiber bend manifest as different strains in each outer core. The center core is not affected by either. Since the fiber is pre-twisted, computation of shape in three dimensions is accurate.

OFS medical fiber is compatible with many well-known interrogators. These include standard wavelength and time division multiplexing (WDM and TDM) as well as optical frequency domain reflectometry (OFDR). In medical applications, OFDR is preferred due to its fine resolution.

When operating on the human body, accuracy could mean the difference between life and death. With the development of shape sensing, surgeons will be able to operate on their patients with much more precision and reduced procedure time. Enhancing existing procedures with shape sensing technology will improve the standard of care in next generation medical procedures.

Written by,

Michael Steinberg and Richard Allen