Laser-induced Damage to Large Core

Optical Fiber by High Peak Laser Power

Adapted from manuscript by Dr. Xiaoguang Sun and Dr. Jie Li | rewrite by Anthea Croghan

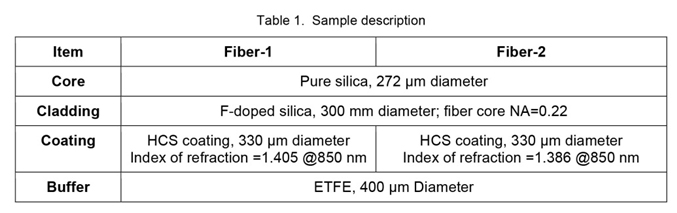

As medical applications are demanding optical fibers to transmit with increasingly higher peak powers and smaller bend diameters, it has become necessary to test and develop fibers that can perform under these strenuous conditions. A study recently completed by Dr. Xiaoguang Sun and Dr. Jie Li of OFS examined laser damage to large core multimode glass optical fibers from high peak laser power, providing important insight into the damage mechanism for a particular failure mode. A two-point bend tester was used on fiber samples prepared with polymer coatings, having different refractive indices. It was found that peak power was one of the main determining factors in performance among the samples. Polymer coatings with lower refractive indices were found to significantly improve fiber resistance to bending while transmitting.

Medical applications utilizing laser delivery fiber often require very small bend diameters. Fiber breaks when put under stress that exceeds its fracture strength, and when transmitting laser it will break at even lower stress levels [3,4]. Fused silica optical fibers are desirable for laser power delivery in many medical applications because of the high laser induced damage threshold (LIDT), high strength, mechanical flexibility, and other beneficial properties such as low optical loss over a wide wavelength range, from UV to Near IR.

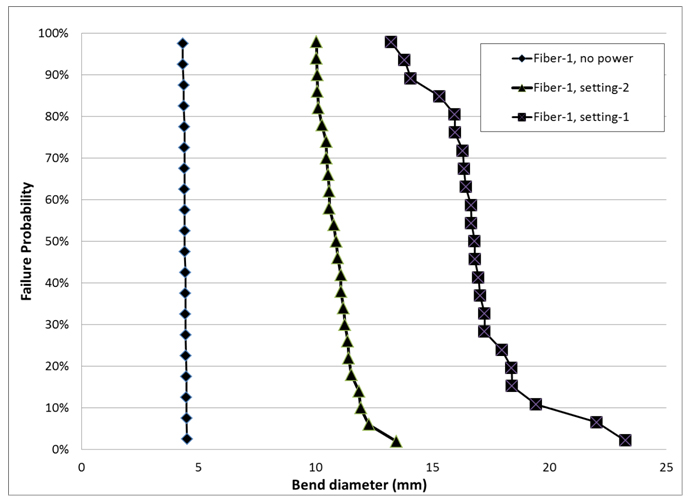

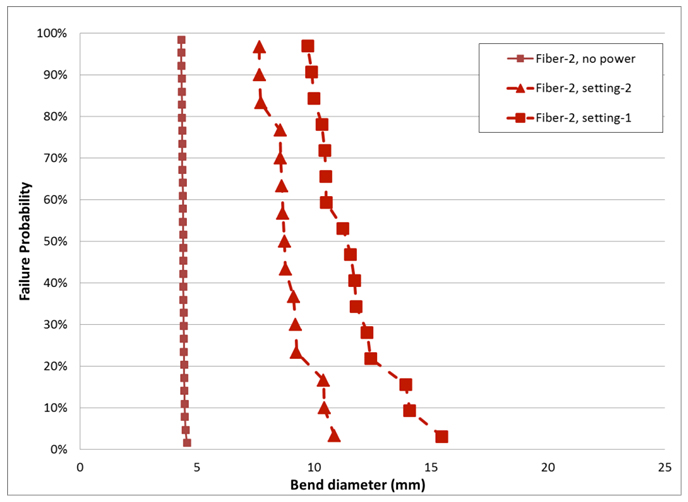

The two fibers, one similar to that of a previous study [4], and one with a lower index coating, were tested. Breaking diameters were measured in a two-point bend tester while transmitting laser at different peak and average powers (peak powers up to 170 kW). The peak power used was much higher than that used in our earlier study (peak power 20 kW) [4] to differentiate between the performance of the fibers with different coatings.

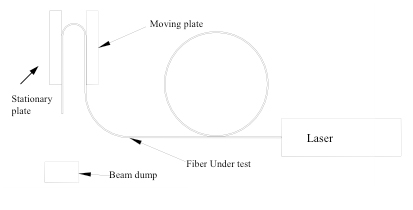

Figure 3. Experimental setup

The power source used was a pulsed Nd:YAG laser from Lee Laser. Two settings were used: 6 kHz (Setting 1) and 24 kHz (Setting 2). The laser output was focused to a 180 µm diameter spot size. The pump power was kept constant. When the pulse repetition rate was increased, the pulse width increased, resulting in a higher average power. The subsequent pulse peak power was lower with a higher pulse repetition rate. The fiber buffer was stripped from a section near the end and the end face was cleaved, and then that section of the fiber was held between the two jaws in the two-point bend tester with a 180° bend at a large bend diameter. While the laser was turned on, the moving plate traveled toward the stationary plate until the fiber broke, at which point the distance between the two plates was recorded.

It is also worth noting that worse degradation was observed at high peak power when the average power was low. We can conclude that the peak power rather than the average power is a determining factor for fiber performance in bend while transmitting laser power. So therefore, our results indicate that peak power is a determining factor for this failure mode. Fibers coated with lower refractive index coating provide better resistance to laser-induced damage.

REFERENCES

[1] James A. Harrington, “An overview of power delivery and laser damage in fibers,” Proc. SPIE Vol. 2966 (1997)

[2] T. Schmidt-Uhlig, P. Karlitschek, G. Marowsky and Y. Sano, “New simplified coupling scheme for the delivery of 20MWNd:YAG laser pulses by large core optical fibers,” Appl. Phys. B, 72, (2001) 183.

[3] Knudsen BE, Glickman RD, Stallman KJ et al, “Performance and safety of holmium: YAG laser optical fibers,” J. Endourol, 1092 – 1097 (2005).

[4] Xiaoguang Sun, Jie Li, Adam Hokansson, “Study of optical fiber damage under tight bend with high optical power at 2140 nm,” Proc. SPIE, Vol. 6433 (2007).

[5] Xiaoguang Sun, Jie Li, Adam Hokansson, Dan Whelan and Michael Clancy, “Study of laser-induced damage to large core silica fiber by Nd:YAG and Alexandrite lasers,” Proc. SPIE, Vol. 7173 (2009)

[6] R.D Maurer, “Behavior of flaw in fused silica fibers” in Strength of inorganic glass, Charles R. Kurkjian,,ed. (Plenium Press 1985)

Written by,

Steve Allen