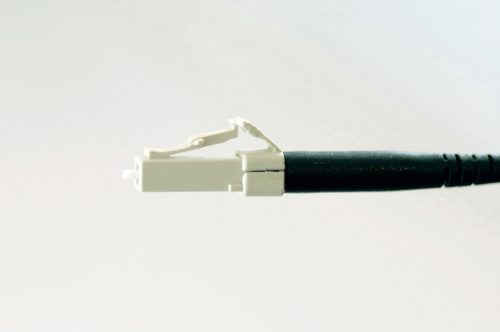

LC Crimp & Cleave Termination Instructions

Leave a Commentfor 50 and 62.5 µm GiHCS®, 200 µm HCS® LC Connectors

Important Safety and Warranty Information

Please Read First!

Please make sure to READ and understand the termination instructions completely. Improper assembly will cause poor termination results and cause damage to termination kit components.

Download the pdf document for the full instructions

Make sure you WEAR eye protection during the termination process. Bare optical fiber is sharp and may splinter; handle very carefully and make use of the provided fiber optic shard disposal container.

For more information please CONTACT the sales representative in your region or call the factory for technical support:

Mon-Friday, 8:00 am-5:00 pm EST.

860-678-6636

770-798-5555 [Outside the USA and Canada]

Content

LC Termination Kit Contents

Related Products and Accessories (Sold Separately)

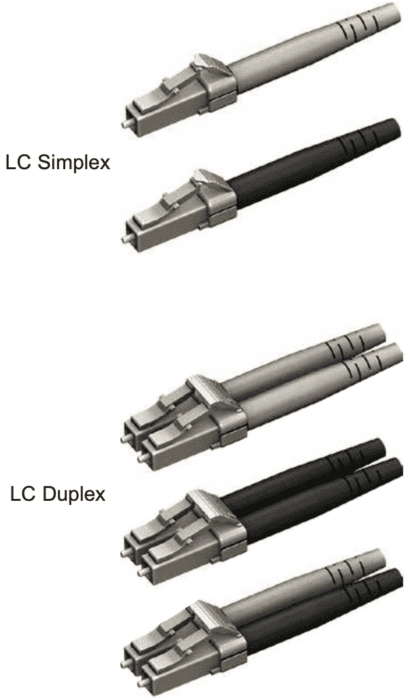

LC and LC Duplex Connectors

Insertion Loss Test Kit

Termination Instructions

Step 1: Slide Strain Relief Boot

Step 2: Remove Outer Cable Jacket

Step 3: Remove ETFE Buffer

Step 4: Install Connector Body

Step 5: Cleave Optical Fiber

Step 6: Install Anti-snag Latch or Duplexing Clip

Maintenance & Trouble Shooting Guide

Importance of Cleave Tool Cleaning

Cleave Tool Cleaning Kit

Troubleshooting

LC Termination Kit Contents

Kit Contents

Part Numbers/Description

DT03732-LC1 . . . . . . . . . . . GiHCS LC Termination Kit

DT03732-LC2 . . . . . . . . . . GiHCS LC Cleave Tool Only

P76859 . . . . . . . . . . . . . . GiHCS LC Instruction Manual

AP01224 . . . . . . . . . . . . . . . . . . . . . . . Cable Strip Tool

BT03865-07 . . . . . . . . . Crimp Tool LC (Black Handles)

CP01229-22 . . . . . . . . . ETFE Buffer Stripper w/ prong tool and brush

AP01225 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Scissors

K60791 . . . . . . . . . . . Optical Fiber Shard Disposal Unit

K60792 . . . . . . . . . . . . . Alcohol Prep Pad (Box of 100)

Other Items Required (not included in kit): Safety Glasses, Marker

Order an OFS LC Termination Kit Number DT03732-LC1 Now

Related Products and Accessories (Sold Separately)

Part Numbers/Description

P26763-01 . . . . . . . . LC Simplex Connector (Beige Boot)

P26763-02 . . . . . . . . . LC Simplex Connector (Black Boot)

P26764-01 . . . . . . . LC Duplex Connector (2 Beige Boots)

P26764-02 . . . . . . . LC Duplex Connector (2 Black Boots)

P26764-03 . . . . . . . . . . . . LC Duplex Connector (1 Beige + 1 Black Boots)

P10188-15 . . . . . . . . . . . . . . . . . . Insertion Loss Test Kit for 50 and 62.5 µm GiHCS LC Connectors

P16247 . . . . . . . . . . . . . . . . . . . . Cleave Tool Cleaning Kit (Includes cleaning fluid and safe cleaning swabs)

STEP 1: Install Strain Relief Boot

Slide STRAIN RELIEF BOOT (tapered end first) onto cable end and slide approximately 3 inches [76 mm] out of way.

STEP 2: Remove Outer Cable Jacket

- Mark cable outer jacket 2.5 inches [63.5 mm] from cable end with a marker

- Using 2nd hole (marked 1.6) from the open side of the cable jacket strip tool, remove the 2.5 inches [63.5 mm] of outer jacket.

STEP 3: Remove ETFE Buffer

- Insert the buffered fiber through the guide tube of the ETFE Buffer Strip Tool, all the way in until the cable jacket bottoms out inside it.

- Holding cable securely, squeeze the tool’s handles to cut ETFE buffer then PULL STRAIGHT to remove the ETFE buffer.

- With alcohol prep pad folded in two, wipe the surface of fiber where the ETFE buffer was just removed.

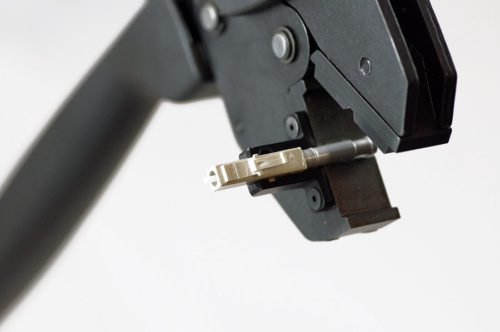

STEP 4: Install Connector Body

- Locate the CONNECTOR BODY subassembly into the CRIMP TOOL nest as shown. Close the crimp tool handles lightly to secure connector in nest, but do not yet apply crimp

- Insert stripped fiber into CONNECTOR BODY subassembly until the cable jacket bottoms out inside the connector

- Squeeze handles of CRIMP TOOL to apply crimp. CRIMP TOOL will not release until fully crimped.

- Remove CONNECTOR from CRIMP TOOL nest. Slide up and

- install BOOT onto CONNECTOR.

- Locate the CONNECTOR BODY subassembly into the CRIMP TOOL nest as shown. Close the crimp tool handles lightly to secure connector in nest, but do not yet apply crimp

- Insert stripped fiber into CONNECTOR BODY subassembly until the cable jacket bottoms out inside the connector

- Squeeze handles of CRIMP TOOL to apply crimp. CRIMP TOOL will not release until fully crimped.

- Remove CONNECTOR from CRIMP TOOL nest. Slide up and

- install BOOT onto CONNECTOR.

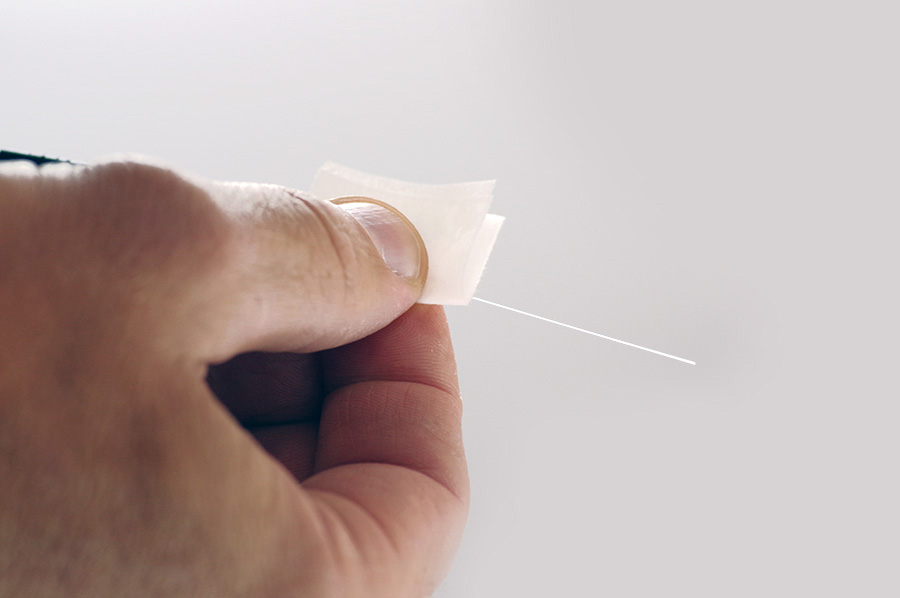

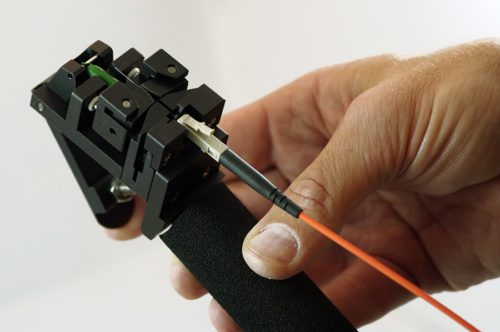

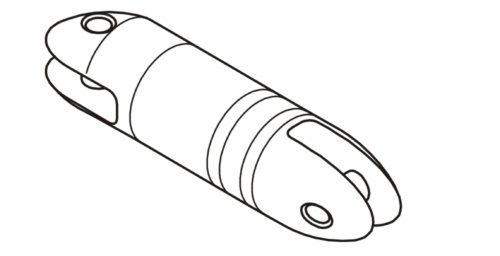

STEP 5: Cleave Optical Fiber

- Holding the CLEAVE TOOL in a horizontal position, grip the handle while leaving your index finger free to actuate trigger

- Gently insert CONNECTOR BODY into cleave tool as shown. Be sure to have it fully inserted and release the CONNECTOR BODY

- Using index finger, slowly depress trigger to perform the cleave operation. The cleave process is complete when the optical fiber snaps away

- from the connector. Do not release the trigger just yet!

- Before releasing the trigger, remove CONNECTOR BODY from the

- cleave tool and grasp the optical fiber scrap while releasing the trigger.

- Gently remove the scrap fiber from the cleave tool while keeping it away from the tool’s diamond blade. Place the scrap optical fiber into the fiber optic shard container for safe disposal.

STEP 6: Install Anti-snag Latch or Duplexing Clip

Simplex Connector:

• Spread the clip slightly as shown.

• Install the clip around the connector, aligning as shown.

• Wrap around and snap on to secure.

Duplex Connector:

• Spread the clip slightly as shown.

• Install the clip around the connectors, aligning as shown.

• Wrap around and snap on to secure.

The PDF document also includes a Cleave Tool Cleaning Guide:

For cleaning your cleave tool, please order the OFS Cleave

Tool Cleaning Kit (part #P16247) which includes recommended cleaning fluid, swabs, and complete instructions.

The PDF document also includes a fiber optic troubleshooting guide for:

- Dim-light termination and no light termination

- Poor cleave quality or high insertion loss

- If the fiber does not cleave

- If the fiber protrudes or recesses after cleave

Download our LC Connector Family Spec Sheet

Visit our Knowledgebase and filter by Installation Resource to find a list of all our fiber optic instructions.

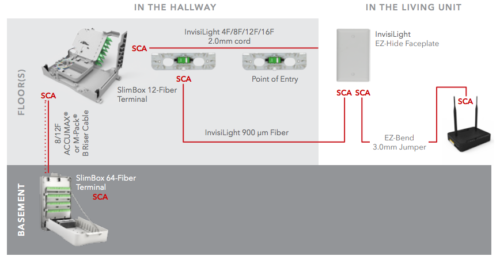

Learn more about our fiber optic building solutions

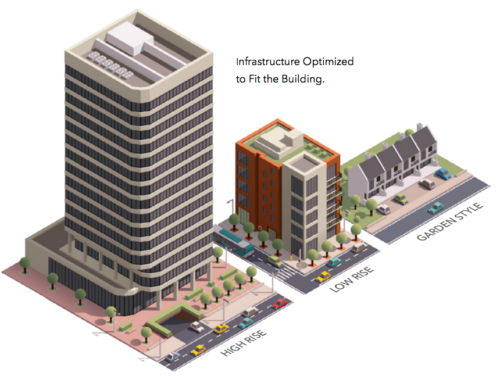

The demand for bandwidth continues unabated, driven by Web 1.0/2.0, mobile and now streaming video. The result is an expected Compound Annual Growth Rate (CAGR) of approximately 22% across the network through 2020.

The demand for bandwidth continues unabated, driven by Web 1.0/2.0, mobile and now streaming video. The result is an expected Compound Annual Growth Rate (CAGR) of approximately 22% across the network through 2020. High resolution video will continue to use bandwidth as it becomes embedded in various networked applications such as telemedicine, remote medical monitoring and distance learning.

High resolution video will continue to use bandwidth as it becomes embedded in various networked applications such as telemedicine, remote medical monitoring and distance learning.

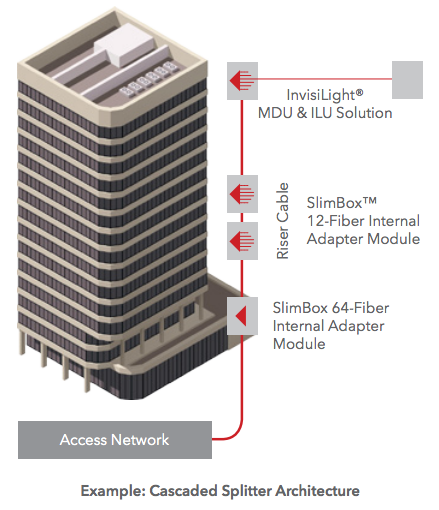

A typical PON network consists of the Optical Line Terminal (OLT) in a central office, head end or

A typical PON network consists of the Optical Line Terminal (OLT) in a central office, head end or

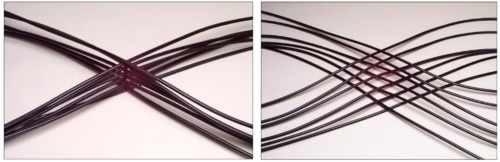

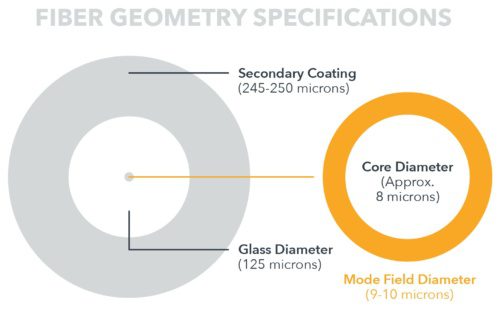

No — it is important to note that not all laser-optimized fiber is 10 Gb/s capable. If 10 Gb/s capacity is in your future, you must make sure that the LOMMF you’re installing now is capable of handling 10 Gb/s. The first laser-optimized fibers, introduced to the market in the mid-1990s, were designed for 1 Gb/s applications. Available in both 62.5/125 µm and 50/125 µm designs, these fibers extended the reach capability of 1 Gb/s systems beyond what the industry standards stated. For instance, OFS 1 Gb/s

No — it is important to note that not all laser-optimized fiber is 10 Gb/s capable. If 10 Gb/s capacity is in your future, you must make sure that the LOMMF you’re installing now is capable of handling 10 Gb/s. The first laser-optimized fibers, introduced to the market in the mid-1990s, were designed for 1 Gb/s applications. Available in both 62.5/125 µm and 50/125 µm designs, these fibers extended the reach capability of 1 Gb/s systems beyond what the industry standards stated. For instance, OFS 1 Gb/s

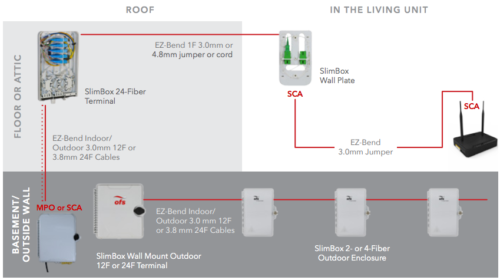

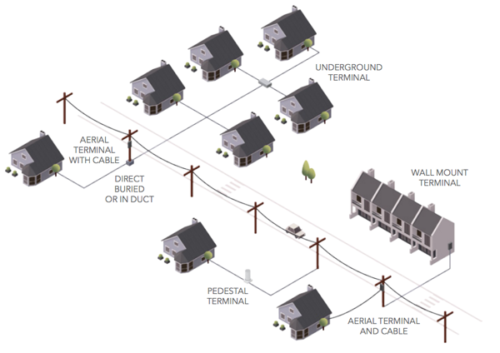

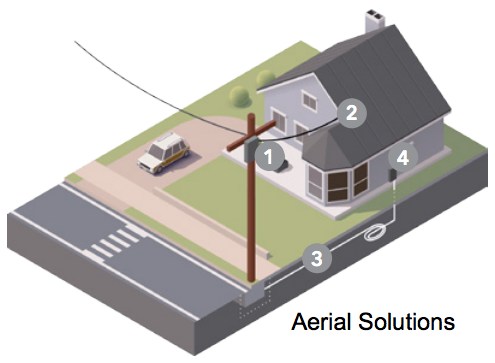

Aerial deployment is typically lower in cost and preferred where poles are in place near homes. In this scenario, a SlimBox® Drop Terminal is installed on a pole, with or without splitters, and then connected by a drop cable to as many as 16 homes. Below grade drop deployment is preferred if there is an existing duct placed from the terminal location to the home, or if below grade cabling is required by local regulations.

Aerial deployment is typically lower in cost and preferred where poles are in place near homes. In this scenario, a SlimBox® Drop Terminal is installed on a pole, with or without splitters, and then connected by a drop cable to as many as 16 homes. Below grade drop deployment is preferred if there is an existing duct placed from the terminal location to the home, or if below grade cabling is required by local regulations. Underground drop cable options include the single-fiber EZ-Bend® 3.0 mm and 4.8 mm Ruggedized Cables and EZ-Bend Toneable Cables. The toneable cables enable easy above ground locating of buried cables to help avoid cable cuts when other underground systems are installed. These drop cables are installed from the aerial terminal down the pole to the ground, and are then buried to minimize disruption to landscaping, or pulled into existing duct. The cable is then connected into a demarcation box installed at the side of the house, ideally in a location close to the ONT on the inside.

Underground drop cable options include the single-fiber EZ-Bend® 3.0 mm and 4.8 mm Ruggedized Cables and EZ-Bend Toneable Cables. The toneable cables enable easy above ground locating of buried cables to help avoid cable cuts when other underground systems are installed. These drop cables are installed from the aerial terminal down the pole to the ground, and are then buried to minimize disruption to landscaping, or pulled into existing duct. The cable is then connected into a demarcation box installed at the side of the house, ideally in a location close to the ONT on the inside.

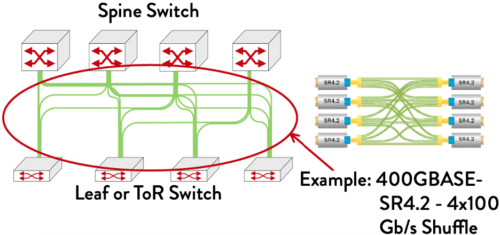

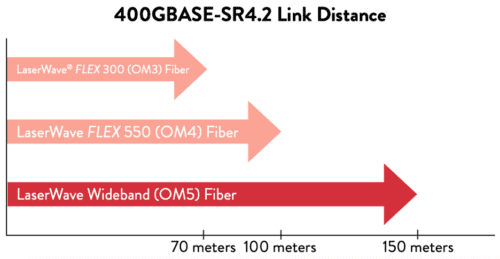

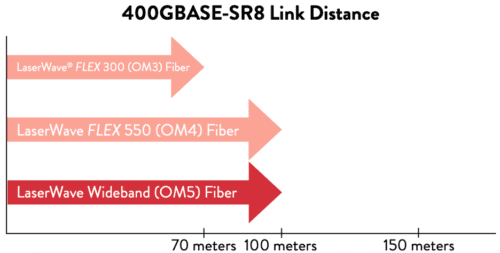

Multimode transceivers also consume less power than single-mode transceivers, an important consideration especially when assessing the cost of powering and cooling a data center. In a large data center with thousands of links, a multimode solution can provide substantial cost savings, from both a transceiver and power/cooling perspective.

Multimode transceivers also consume less power than single-mode transceivers, an important consideration especially when assessing the cost of powering and cooling a data center. In a large data center with thousands of links, a multimode solution can provide substantial cost savings, from both a transceiver and power/cooling perspective. Beyond the reach of multimode optical fibers, it becomes necessary to use single-mode optical fiber. However, when assessing single-mode optical fibers, be sure to consider newer options. A bend-insensitive, full-spectrum single-mode optical fiber provides more transceiver options, greater bandwidth and is less sensitive to handling of the cables and patch cords than is conventional single-mode optical fiber.

Beyond the reach of multimode optical fibers, it becomes necessary to use single-mode optical fiber. However, when assessing single-mode optical fibers, be sure to consider newer options. A bend-insensitive, full-spectrum single-mode optical fiber provides more transceiver options, greater bandwidth and is less sensitive to handling of the cables and patch cords than is conventional single-mode optical fiber.

Industry standards groups including IEEE (Ethernet), INCITS (Fibre Channel), TIA, ISO/IEC and others continue to include multimode optical fiber as the short reach solution for next generation speeds. This designation reinforces multimode optical fiber’s continued economic advantage for these applications.

Industry standards groups including IEEE (Ethernet), INCITS (Fibre Channel), TIA, ISO/IEC and others continue to include multimode optical fiber as the short reach solution for next generation speeds. This designation reinforces multimode optical fiber’s continued economic advantage for these applications.