What is a fiber optic cable?

A fiber optic cable contains anywhere from one to several hundred optical fibers within a plastic casing. Fiber optic cable (or optical fiber cable) transfers data signals in the form of light and travel anywhere from a few feet to hundreds of miles significantly faster than signals in traditional copper cables.

>> View our Fiber Optic Cable Offerings on our Catalog

What are fiber optic cables made of?

Fiber optic cables are made up of glass fibers that transmit light signals over short and long distances. They are used in industrial communications settings as well as telecommunications networks for high-speed data transmission. They are also used to transmit high-power laser energy in such applications as medical lasers for surgery and military laser defense systems. In communications applications, optical fibers are replacing copper wire because they can carry much more information than copper does and at much higher speeds.

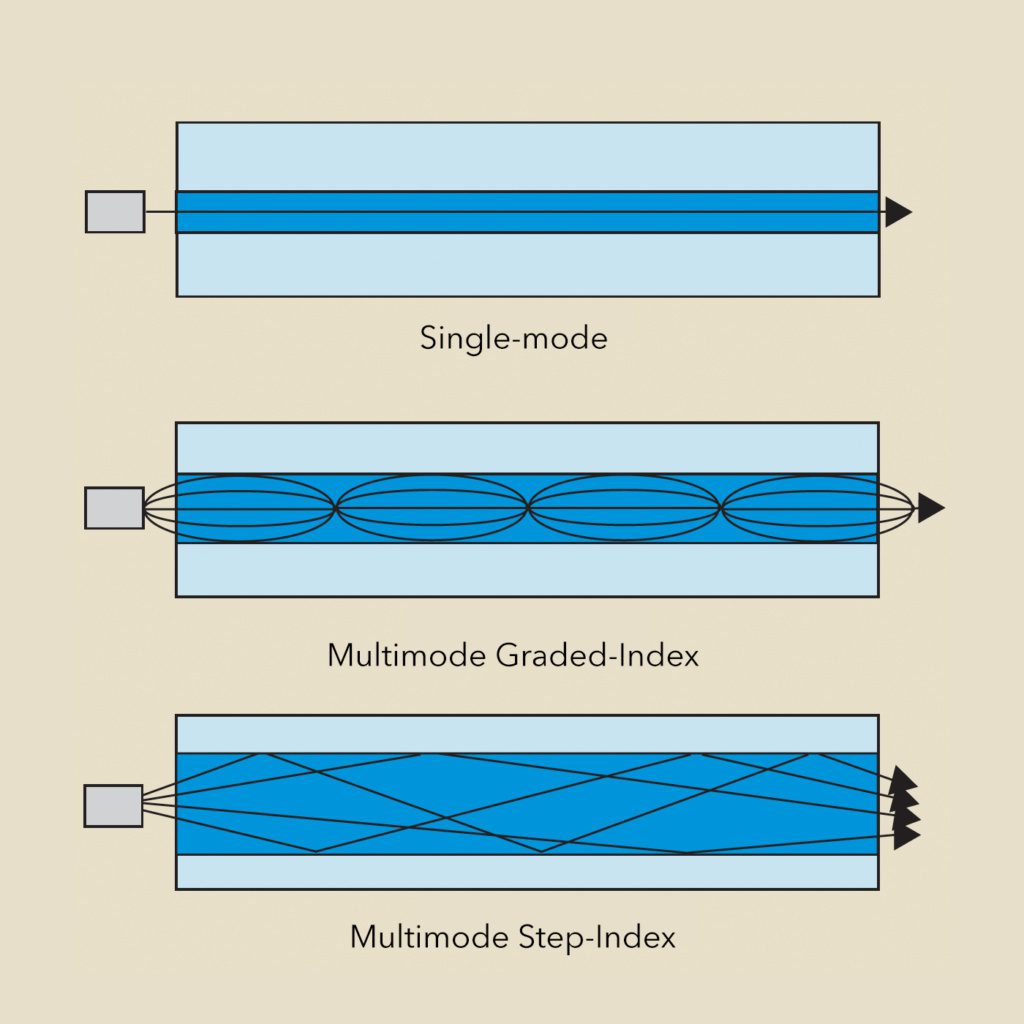

What are the 2 main types of optical fiber?

There are two main categories of optical fibers: single-mode and multimode. “Mode” refers to a ray of light traveling down the fiber. Multimode (multiple rays of light) fiber is further classified as either graded-index or step-index. The index profile describes the way the multiple rays of light travel down the fiber. In a multimode graded-index fiber, the light travels in a sinusoidal pattern down the length of the fiber to arrive at the end pretty much all at the same time. This type of multimode fiber is used in a short distance, data communications networks such as within a building or between buildings in an office park. In a multimode step-index fiber, the multiple rays of light travel down the fiber in a haphazard manner with each ray arriving at the end at different times. These types of fibers are also used in short-distance, harsh industrial and aerospace environments to provide secure communications. Larger core multimode step-index fibers may be used to transmit laser energy in places like the operating room, to clean graffiti from historical monuments, and to direct energy in military defense systems. Multimode fibers vary in core size from 50 to 2000 microns. They may be made from pure silica quartz, plastic, or other materials.

Single-mode fiber is designed to allow only one ray of light to travel down its path. The single ray travels the length of the fiber in a step-index pattern. This type of fiber can carry very large amounts of data (e.g., hundreds of phone calls) over very long distances, between cities, regions, countries, and continents when laid on the ocean floor.

What are the main types of fiber optic cables?

Fiber optic cables come in various constructions depending on the end-use. They range anywhere from a simplex construction (one strand of fiber with an outer PVC or other plastic) to cables consisting of hundreds of fibers grouped in tubes and stranded around a central strength member with a plastic outer jacket. Multimode fibers are usually constructed in simplex, duplex, zipcord designs and may be either tight-buffer or loose-tube configurations that incorporate anywhere from 1 to several 10’s of fibers. Single-mode fiber optic cable constructions are more complex and may incorporate hundreds of optical fibers.

The cable construction for either type of optical fiber cable is there to provide protection to the optical fiber inside: Protection from excessive bending, crushing, strenuous pulling, etc. The outer jacket of the cable may be made from a variety of plastic materials ranging from PVC to Polyurethane to Polyethylene to name a few.

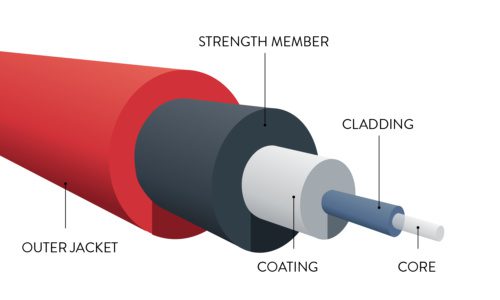

What are the main components of a fiber optic cable?

The number of components making up a fiber optic cable will vary depending on the end-use. Some designs are simple when applications are light-duty. The harsher the environment the fiber optic cable will be exposed to, the more complex the cable structure. In simple terms, a fiber optic cable has 5 basic components:

- The core of the optical fiber which may vary in size between 8 microns and 2000 microns.

- The cladding which is the layer that surrounds the core. This is usually silica and can sometimes be plastic.

- The coating. This is the outer layer of the optical fiber. It is extruded and may be colored for easy identification in multi-fiber cables.

- A strength member which will provide additional protection from breakage / signal deterioration.

- An outer jacket to provide a final layer of protection for the optical fiber inside.

How many fibers are in a fiber optic cable?

The number of fibers in a fiber optic cable is called “fiber count”. Fiber count will vary depending on the application. Today, it can range from one fiber up to about 7,000 fibers. Cable manufacturers are continually finding ways to increase fiber count to accommodate the growing demand for bandwidth.

Do fiber optic cables get hot?

No. Fiber optics are not heated by the light they carry, and therefore do not emit heat or cause any other type of heating effect.

What happens if fiber optic cable gets too hot?

Fiber optic cables can be damaged by heat. If the temperature of the cable exceeds the manufacturer’s recommended temperature range for storage and operation, the cable jacket will no longer protect the fiber inside which could lead to increased attenuation (signal weakening) and possible breakage of the fiber.

Does cold weather affect fiber optic cable?

Fiber optic cables are designed to operate in a wide range of temperatures including very cold temperatures. The manufacturer selects jacketing material based on the end-users environmental factors. The manufacturer will specify the storage and operating temperature range for the cable it produces.

What is so special about fiber optic cables?

Optical fibers transmit data via photons (light particles) as opposed to copper cables which do so electronically. Data travels at the speed of light in fiber designed for long-distance networks. Data cannot travel as fast or as far in copper cables. Also, unlike copper cables, fiber optic cables are immune to EMI (Electromagnetic Interference). Fiber optic cables are used extensively throughout our society today because they provide the data speeds and bandwidth necessary to make the internet of things (IOT) possible.

>> Learn About OFS Fiber Optic Cables

Why is fiber optic cable very popular?

The main reason for the popularity of optical fiber in telecommunications and data transmission applications is that it offers a number of advantages over copper wire. These include:

• Optical fiber has no electrical resistance, so there are no losses due to heat generated by current flow through the conductor;

• The speed at which signals can be transmitted using optical fiber is much greater than with conventional conductors.

Which type of fiber is most widely used?

Single-mode optical fibers account for the largest volume of optical fiber manufactured today. Single-mode fiber optic cables link cities, regions, countries, continents. They are installed aerially, underground, and on the ocean floors.

>>Download Our Guide Now

When would you use fiber optic cable?

A service provider would install fiber optic cable when the demand for large quantities of data is required to be transmitted with little loss over significant distances. Optical fiber would also be used by OEM’s who need to transmit laser energy over a short distance. Optical fiber would be the choice if avoidance of EMI is a key requirement.

Are fiber optic cables expensive?

Fiber optic cables are now inexpensive enough that they are being installed to and within individual homes and offices around the world.

How long does a fiber optic cable last?

Fiber optic cables are very durable and can withstand extreme temperatures and conditions. When designed and installed per industry-standard recommendations, fiber optic cables have no known expiration date.

How is fiber optic cable installed?

Specific installation practices are available from manufacturers depending on the type of fiber optic cable being installed. Installations can be performed aerially on poles or underground, either via a direct buried approach or in ducts. Once this has been completed, the installer must then install the various components that make up the optical system: splices, connectors, etc. Finally, once all these elements have been properly connected, they are tested to ensure proper operation.