The use of optical fiber and fiber-optic based sensors in the medical market is constantly growing. Prior to use inside the human body, fibers must be sterilized to ensure they are free of microorganisms and perform well during invasive and noninvasive medical applications such as urology, general surgery, ophthalmology, cardiology, endoscopy, dentistry, and medical sensing. OFS tested optical fibers with four separate coatings to see the effects of sterilization on attenuation and mechanical strength. Sterilization can generally be defined as any process that destroys all microbial life such as fungi, bacteria, and virus or spore forms. Before our testing, there were only a few studies directly or indirectly related to effects of sterilization on optical and mechanical properties of optical fibers which is why we felt real data knowledge and experience was at the utmost importance in order to best recommend materials for different types of sterilization in addition to which sterilization methods work best.

Ideally, sterilization of optical fibers should be such that it eliminates all the microorganisms but does not affect optical attenuation and mechanical strength. All fibers selected for this study were OFS products. The fibers had 200 µm silica glass cores and 220 µm doped silica claddings with a numerical aperture (NA) of 0.22. As shown in table 1, each of the optical fibers was drawn with four different polymer coatings: dual acrylate, hard fluoropolymer cladding (such as that found on HCS® optical fiber), silicone, and polyimide. The sterilization methods used in this study included: 1) treatment with peracetic acid (PAA), 2) exposure to UV radiation and 3) exposure to electron beam (E-Beam) radiation. Each sterilization method contains certain advantages. PAA is a highly biocidal oxidizer and can effectively kill bacteria, fungi, and yeasts. UV radiation is the easiest and most environmentally friendly sterilization technique. E-Beam is also much safer in operation than gamma radiation because it does not use radioactive materials.

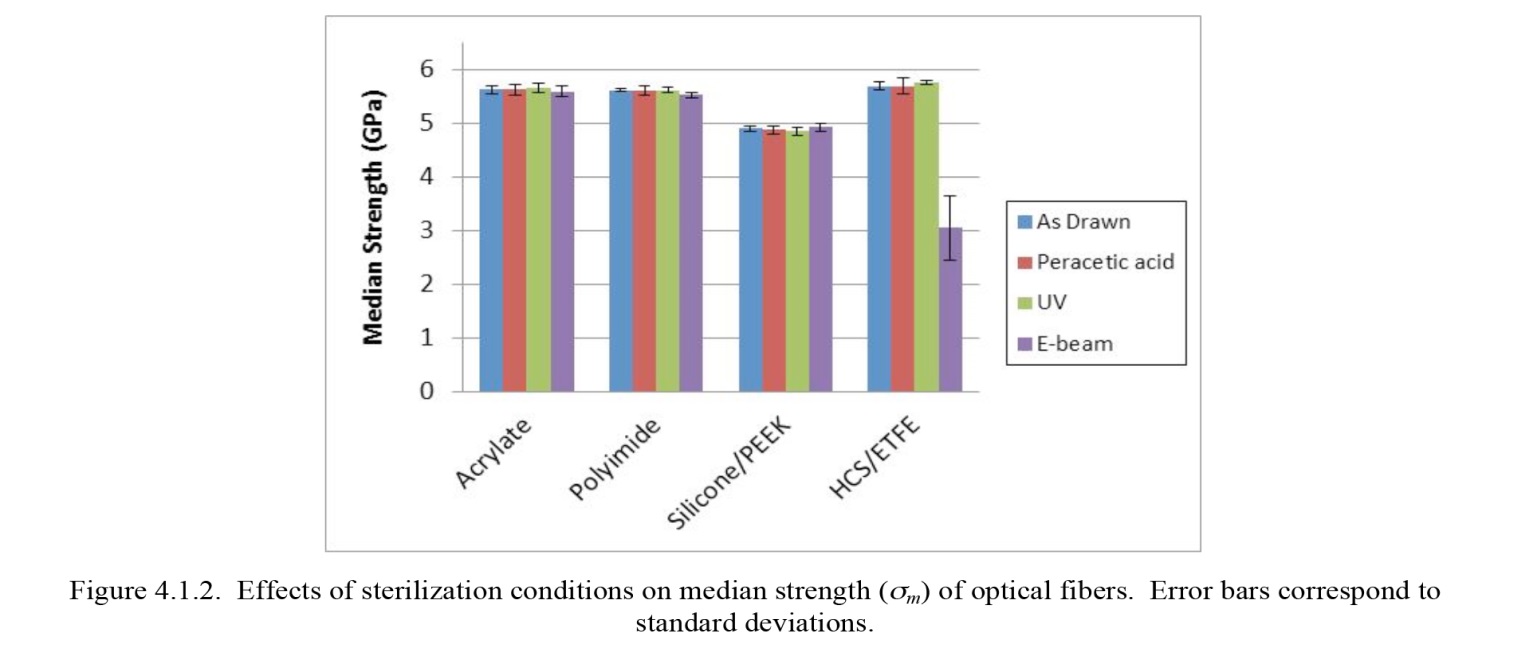

As you can see in figure 1 the only major difference in mechanical strength between “as drawn” and post sterilization fiber occurred in the HCS/ETFE coated fiber after E-Beam sterilization. All other coating and sterilization technique combinations displayed insignificant strength loss. PAA and UV sterilization methods do not affect the mechanical strength of the fibers. Due to similar results generated in past testing with gamma radiation, it was concluded that the strength degradation observed in the HCS/ETFE optical fiber is due to the fact that the coating and buffer materials are strongly fluorinated. Fluorine containing polymers are known to be much more sensitive to radiation than fluorine free polymers.

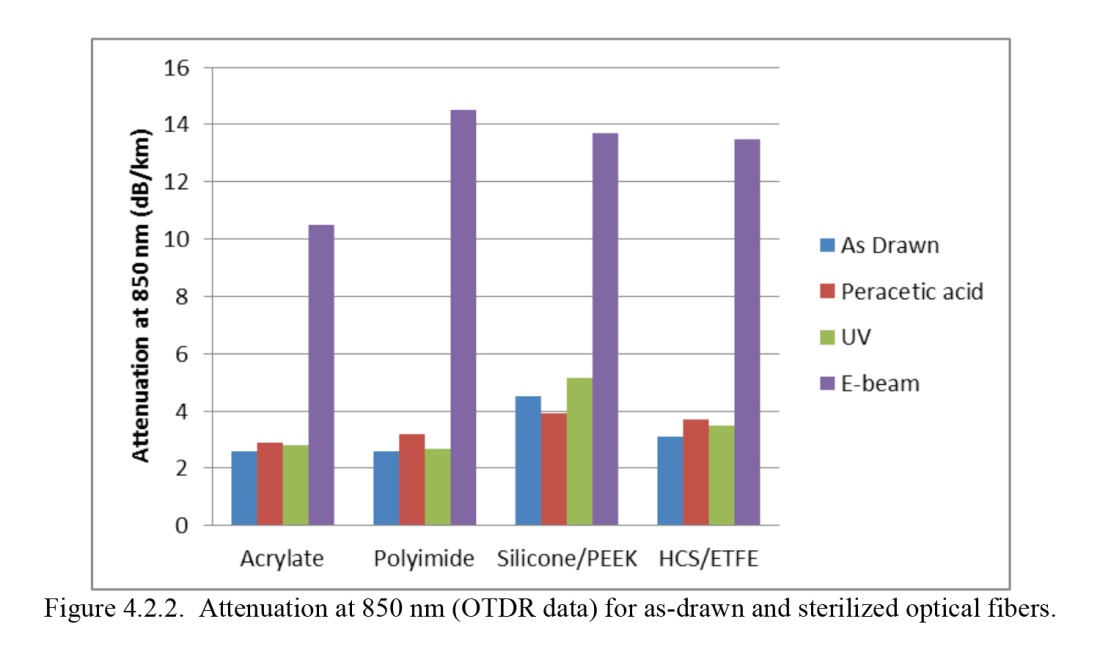

Figure 2 displays the effects of sterilization on optical fiber attenuation. PAA and UV exposures did not affect the optical loss in any of the coating / sterilization combinations. However, there is a strong effect from the E-Beam sterilization on all four coating combinations. The use of E-Beam radiation induces certain defects in the core of the optical fiber which increases the attenuation. From this data, we are able to determine that the E-Beam radiation is not the best method of sterilization even for fibers with non-fluorinated coatings.

With this research, OFS concludes that PAA and UV sterilization are preferred over E-Beam sterilization. Until the increase in attenuation can be better controlled, E-beam should not be used as a sterilization method. Through testing and research, we are able to relay important information and recommend the best techniques possible to sterilize OFS fibers.

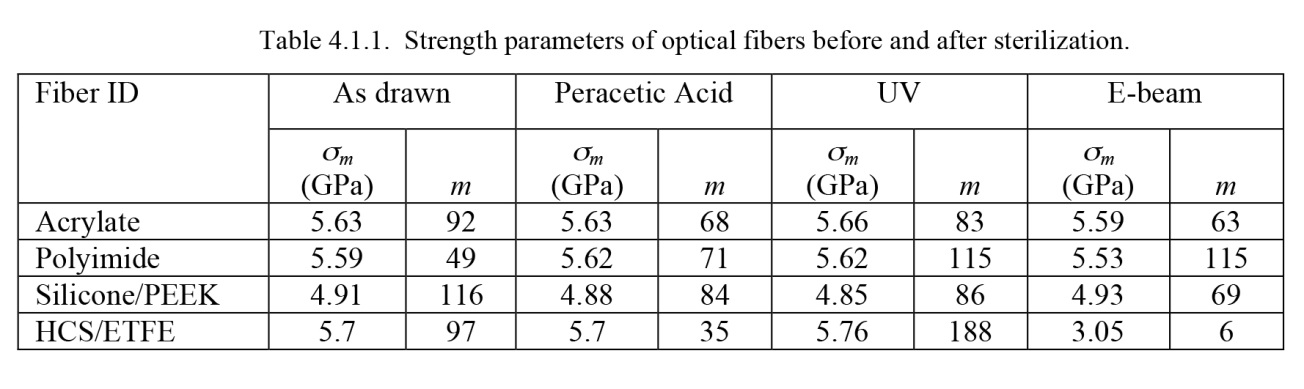

Table 1

It is common to describe the fracture stress data by a Weibull distribution, which characteristic parameters are the median strength (equivalent to the median fracture test, m) and the Weibull slope, m.

Figure 2

By,

Michael Steinberg