Transcript:

Sandy Oregon located about 30 miles from downtown Portland is blessed with beautiful mountain scenery but unfortunately its great location also leads to challenges when it comes to being connected to the outside world. In 2002 city officials had the vision to start their own internet service provider and offer affordable internet service to its residents. The result was SandyNet. From the beginning it was a huge success. People wanted it. They were hungry for it.

We had been in municipal ISP for quite some time starting off with DSL and wireless and outgrown that technology and so really the only next step for technology was to go to fiber. So, in 2014 SandyNet partnered with OFS to bring high-speed fiber to Sandy’s businesses and residents. They set some specific goals at the time that included deploying a future-proof fiber optic network. Providing all neighborhoods with the same service enabling residents the ability to access videos, e-learning, gaming, and government services, increasing Sandy’s competitiveness to attract new business and offering the city-owned network as a utility. In the years since upgrading to a fiber optic network, how has Sandy done with meeting their goals?

Sandy’s seeing some unprecedented growth right now both on the residential side and a lot of commercial opportunities. Going forward, SandyNet will continue to help lure people here and increase our tax base, increase our residence and increase the virtual learning environment that a lot of our students are partaking in. Right now, over the course of the last six seven years, during that time period I’ve talked to a number of people in Sandy who have moved here to the community and while it wasn’t the sole decision that they made the fact that gigabit fiber was available at their residence in a wired solution was the deciding factor for several people to buy a house in this community.

Our community has just thrived with having that big fat fiber pipe. That’s one of the things for us where we were always struggling with the amount of capacity that our previous internet service providers were giving to us. Now we don’t have that problem anymore. We have over capacity in a sense. We have enough to where people can stream and listen to music while they’re working and we can still get all our work done. We can download the data that we need to get it done in minutes, seconds. Instead of an hour or two, we can upload stuff into our servers, into our clients servers, quickly just all of that greatness that comes with having a really fast internet connection.

It’s a great asset to have our SandyNet charges on the same utility bill that our water and sewer charges are on. It’s an easy one payment a month to have this service that you know is much more affordable than a lot of the other providers that are out both in our area and nationally.

But back in 2014 when SandyNet was deploying fiber to try and make its network future proof no one could have foreseen what fiber would mean to not just the town but the entire world in 2020. There was virtually no one whose life was not affected by the COVID-19 pandemic. Having a high speed fiber optic network became the difference between those who were able to keep pace with the world and those who were left wanting something better. It was amazing that we got our fiber put in place when we did. It was built out to so many homes and had gone in front of hundreds of the homes in Sandy. Those that didn’t initially take it, could get it during that time. There was no rationing. We were in school one day and then everyone was at home the next day. Not just students, but also people working from home.

When you have a strand of fiber going to your house providing gigabit capacity it makes working from home very easy and I think a lot of people have been very happy with the service that they’ve gotten here in Sandy. From council meetings being held virtually, to team meetings, and other department meetings at the administrative level, we were able to continue our operations seamlessly with the help of SandyNet During the pandemic we did see an increase in speed upwards of 25 across our overall traffic patterns. Mostly traffic did increase during the workday. Our network is designed to be able to carry that load.

Once the city of Sandy decided to go all in with fiber who better to turn to than OFS. The industry leading experts at OFS were able to design, engineer, and deploy a network that was easily able to meet all of Sandy’s goals for a robust future-proof network.

OFS is able to combine several products that are designed to work with the gigabit, and 10 gigabit, 25 gigabit fiber. OFS can integrate solutions together to provide a complete turnkey solution for fiber to the home to our customers. We have to thank OFS a lot for SandyNet. We can’t go out and buy a book on how to set up fiber to the home network. Working with people that have been in the industry for 30 some years and having a great team that has worked on fiber the home projects in the past has been great. OFS has done all the heavy lifting. They’ve figured out all the optical budget information and then just provided this seamless solution and high-quality product.

Sandy’s been a fantastic success. We really appreciate all the opportunities from the city of Sandy for OFS. A complete OFS product solution along with the design the engineering, the build has provided the city of Sandy residents with great economic enhancement and quality of life improvement for decades to come. It would be a lot harder to differentiate Sandy from any other city of 12,000 people in Oregon. We still have many things that make us unique, but SandyNet really is the biggest one and I think it will have the most impact on our community over time.

We invite you on a tour of our fiber optic cable manufacturing facilities in Carrollton, Georgia, USA. View the highly automated OFS manufacturing process that produces a wide variety of fiber optic cables and products for telecommunications applications. Loose tube, microcables, flat ribbon, ADSS, ultra high density rollable ribbon cables and premise cables are all made here.

What is Fiber Optic Cable Made up of?

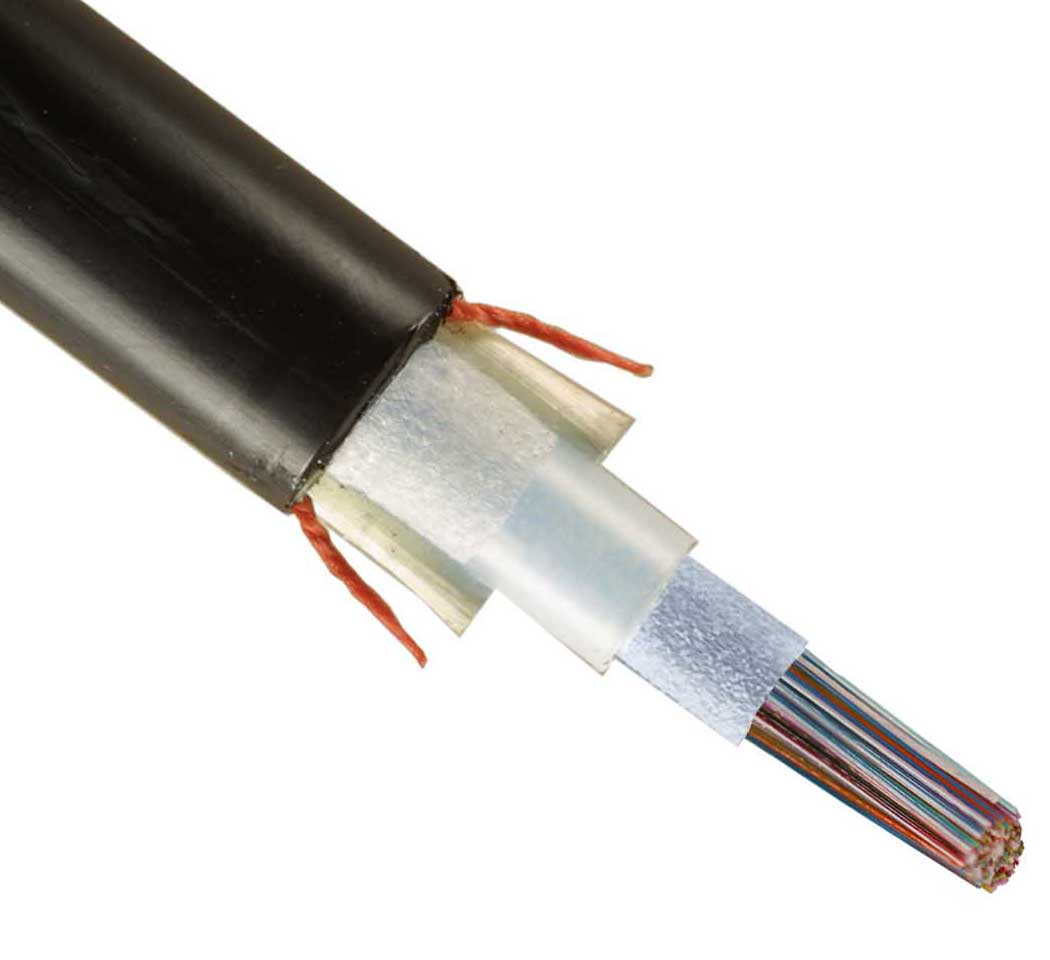

Fiber optic cables are made up of several components: a core, cladding, jacket, and strength members.

The core is the optical fiber itself which is a continuous strand of ultra-thin glass.

Within the core, there are two highly specialized glass coatings called cladding and jacketing.

The cladding helps bounce back imperceptible light signals as they travel along the cable by reflecting off of its walls.

The jacketing protects the delicate optical fibers from mechanical damage and environmental effects.

Lastly, strength members such as aramid yarns or steel wires are used to reinforce and protect the cable further against bending or stretching forces. Together these components form a fiber optic cable that carries light signals over long distances without signal loss or interference.

The Carrollton facility is vertically integrated, with fiber delivered on a daily basis from the OFS Norcross facility, approximately one hour away.

The manufacturing facility is registered in compliance with the ISO 9001, ISO 14000, and TL 9000 standards. Traceability is maintained through every step of the process and ultimately back to the incoming fiber. The facility also has a fully functional product qualification lab and cable installation test track.

OFS Uses Both 200 and 250 Micron Fibers

OFS makes several different fiber structures in the Carrollton facility, including loose tube, flat ribbon and rollable ribbon structures. These structures are used in different cable types and applications.

Statistical Process Control Techniques

Each stage in the manufacturing process is highly controlled with appropriate dimensional targets and tolerances.

Colored ink is applied to the Fiber

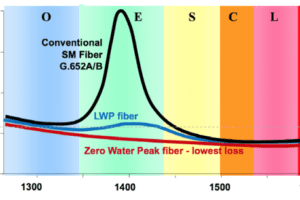

The industry standard color code is used to provide clear identification of the fibers over their lifetimes. Colored ink is applied to specified thicknesses, cured, and respooled for the next step in the process.

Buffer Tube Manufacturing Process

To make loose tubes, fibers or ribbons are paid off of their spools and a buffer tube is extruded around them. The Carrollton plant makes gel-free and gel-filled buffer tubes of different materials, including polypropylene and PBT. Different sized buffer tubes are used for different product types. Buffer tubes used in outside plant applications include either water blocking materials impregnated with super absorbent polymer or gel.

Ribbon Manufacturing Process

A matrix material is applied to the fibers to bind them together so they can be spliced as a group. 12 and 24 fiber flat ribbons are most common. Fiber color code alignment and geometric specifications are very important so ribbons can be spliced and connected in the field.

Rollable ribbons are only partially bonded together, enabling them to be rolled into a cylindrical package. Rollable ribbons are only partially bonded together, enabling them to be rolled into a cylindrical package. Since circles are more space efficient than rectangles, rollable ribbons cables can hold twice the fibers as comparable sized flat ribbon cables. Since these fibers are partially bonded, they can be easily spliced either as single fibers or as a ribbon, giving more deployment flexibility to the network operator.

Cabling

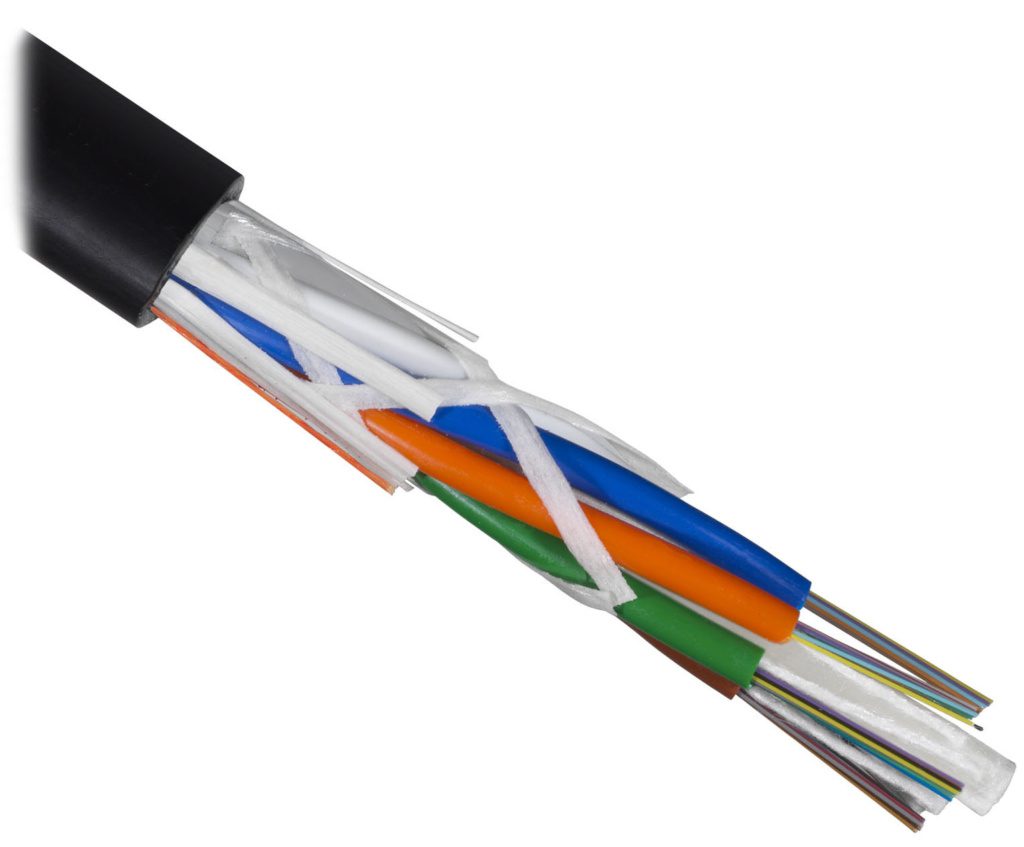

OFS makes two main types of cables – stranded cables and central tube cables.

Stranded cables are made by stranding tubes of fibers, flat ribbons, or rollable ribbons around a central member. Stranded cables are often used in applications requiring frequent access to fibers.

Central tube cables are made by extruding a central tube around a fiber structure. Central tube cables can provide higher fiber density.

Strength

Strength members, including fiberglass and aramid yarns are used to limit the strain on cables and fiber when tension is applied to cables.

Water Blocking Materials

Yarns and tapes are added to provide water blocking outside the core of the cable.

For direct-buried cables, one or more steel armor layers may be added to provide rodent resistance and toning capability.

Outer Jacket

Different versions of polyethylene are used for the majority of outside plant cables. For inside plant or indoor/outdoor cables, materials are chosen to include appropriate flame and smoke resistance.

Type of cable, date of manufacture, length and a unique serial number that can enable traceability through the manufacturing process is printed.

Final Testing

Once manufacturing is complete, the finished cable undergoes final testing for length and optical properties.

Shipping

Cables are then packaged for shipment and loaded on trucks to their final destination.

AccuCore HCF™ Optical Fiber Cable is the world’s first terrestrial hollow-core fiber (HCF) cable solution. Light travels about 50% faster in a hollow core optical fiber compared to the solid silica core of conventional fiber. Consequently, light transmitted in a hollow-core fiber arrives 1.54 microseconds faster for each kilometer traveled compared with conventional optical fiber.

The AccuCore HCF Optical Fiber Cable solution includes indoor/outdoor cable and termination with standard connectors, which are fusion-spliced to the patented photonic bandgap hollow-core fiber. OFS also offers installation services and both passive and active component selection to meet customer requirements. AccuCore HCF optical fiber cable has been successfully deployed, carrying live traffic in several networks.

This latest development from OFS was presented as a postdeadline paper on March 12, 2020 at the Optical Fiber Communication Conference and Exhibition (OFC) held in San Diego. OFC postdeadline papers represent the latest and most advanced technical achievements in the field. The paper reported error-free transmission of direct-detection 10 Gb/s DWDM signals over 3.1 km of cascaded cabled HCF. This is the first time that transmission results in a cabled HCF have been reported. That white paper is available here.

Contact OFS to learn more about AccuCore HCF fiber optic products.

Optical fiber-to-the-business deployment is accelerating globally to support increasing internet speeds of up to 1 Gigabit per second, and 10 Gigabit speeds that are already available in some regions. Service providers are responding by installing optical fiber both to and deep inside buildings to the living unit.

The Solutions in this 64-page guide can help reduce both first and life cycle costs of optical fiber deployments to residential and business customers.

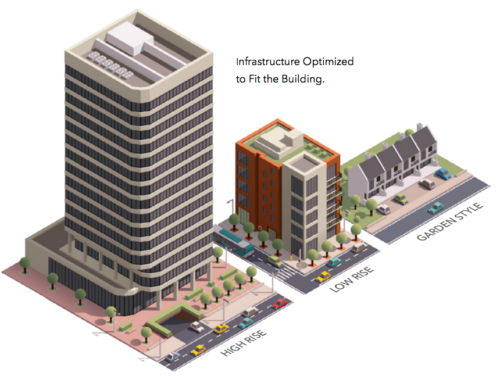

Solutions for both Greenfield installation during building construction and Brownfield installation in existing buildings are included. Scalable and optimized to fit a broad range of building structures, these solutions offer faster, reliable installation through innovative labor saving technologies, using less space than conventional approaches.

Solutions for both indoor and outdoor deployment offer flexibility to use the best available pathways for each building. The solution building blocks include a wide range of terminals, splitters, point-of-entry modules, riser cables, attic and wall fish fiber, hallway fiber and complete indoor living unit fiber kits. This portfolio allows service providers to select the best solution for each building, and OFS can help design building specific solutions and bills of material as a value added service.

>> DOWNLOAD OUR GUIDE NOW

FIBER TO THE BUILDING BENEFITS

OFS fiber-to-the-subscriber (FTTx) solutions help to revolutionize the speed of installing fibers; enhance the customer experience; minimize disruption; reduce labor costs; increase subscriber take rates; enable faster time to revenue for service providers; and get Gigabit and higher speeds faster to subscribers.

OPTICAL FIBER BUILDING CHALLENGES AND SOLUTIONS

- Time to revenue: Fast and easy to install pre-terminated solutions can speed installation and reduce labor costs.

- No pathways, requiring labor intensive cut and patch: Compact surface mounted fiber solutions.

- Limited closet space: Smaller enclosures can enable installation of multiple operator connections in a small telecommunications closet.

- Multiple boxes for splicing and splitter connections: Single box pre-terminated solutions can require less space and enable faster provisioning.

- No duct space: Compact surface mounted fiber solutions either inside or on the outside of the building do not require duct.

- Shared infrastructure: Compact cables can support multiple service providers in telecommunication pathways.

- Fiber bends around many corners: Bend-insensitive fiber specified to support bend radius as low as 2.5 mm.

- Disruptive/noisy to tenants: Optical solutions that are virtually invisible can be installed quickly and quietly and preserve the building decor.

- Service disruptions and lost subscribers: Full solution of fiber, cable and connectors from one company, designed to work together. Factory tested to Tier 1 standards.

- Multiple building types: Solutions to fit each building type.

PRE-TERMINATED vs. FIELD TERMINATED OPTICAL FIBER

Pre-terminated solutions are increasingly used to install fiber in Multiple Dwelling Unit (MDU) buildings to save time and money in higher labor cost regions. Pre-terminated products with built-in slack management are preferred so installers can neatly manage excess slack and use a single component to support multiple deployment lengths. Nevertheless, field terminated solutions can complement pre-terminated parts of the indoor or outdoor network and, for low labor cost markets, field terminated solutions may be preferred. OFS offers both pre-terminated and field terminated solutions to fit the needs of each service provider.

OPTICAL FIBER SPECIFICATIONS OPTIMIZED TO THE APPLICATION

Installing optical fiber in buildings and homes often requires conforming the fiber around sharp corners. EZ- Bend® Single-Mode Fiber offers outstanding bend performance down to a 2.5 mm radius for the most challenging in-residence and MDU applications. Compatible with the installed base of conventional G.652.D single-mode fibers, the fiber meets and exceeds ITU-T G.657.B3 recommendations. EZ-Bend fiber uses patented, groundbreaking EZ-Bend Optical Technology from OFS to provide three times lower loss at tight bends than competing G.657.B3 products.

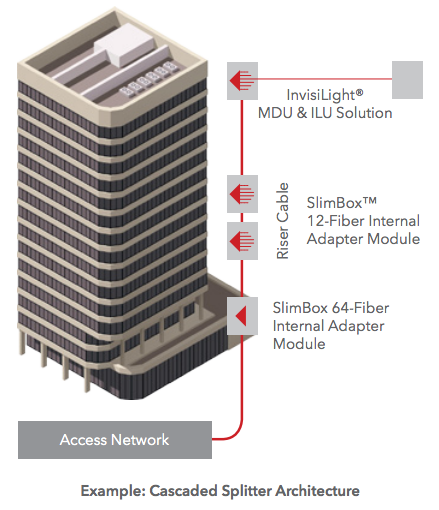

Centralized, Distributed and Distributed Cascaded Splitting

As FTTx deployment accelerates globally to meet increasing bandwidth needs, service providers must install optical fiber both to and inside the building for business and residential subscribers. Building types include duplexes, garden style, low rise (less than 10 floors), mid rise (10 to 15 floors), high rise (16 to 40 floors) and skyscrapers (40 floors and above). To provide building Gigabit services, providers must place optical cables in building risers and ducts, install optical fiber in hallways, and then take this fiber deep into the units, connecting to an indoor Optical Network Terminal (ONT). How can providers accomplish this in buildings that can vary widely in design, materials and available pathways?

Splitter Architectures

A typical PON network consists of the Optical Line Terminal (OLT) in a central office, head end or cabinet, connected by a feeder cable to optical splitters, and then to distribution cables downstream in the network. Choosing the right architecture depends upon end-user density, projected subscription rates and distance from the OLT. Splitter placement is important in FTTx design as it can significantly affect plant and electronics costs.

A typical PON network consists of the Optical Line Terminal (OLT) in a central office, head end or cabinet, connected by a feeder cable to optical splitters, and then to distribution cables downstream in the network. Choosing the right architecture depends upon end-user density, projected subscription rates and distance from the OLT. Splitter placement is important in FTTx design as it can significantly affect plant and electronics costs.

Three common types of splitter architectures are used when deploying FTTx:

- Centralized splitting

- Distributed splitting

- Distributed cascaded splitting

To help meet these needs, the OFS portfolio supports all three splitter architectures, and features a broad range of solutions to meet the requirements of virtually any MDU deployment. For flexibility and regional preferences, these offers include a mix of pre-connectorized, in-field fusion splicing and mechanical connector solutions from which OFS can configure customized designs for each type of building.

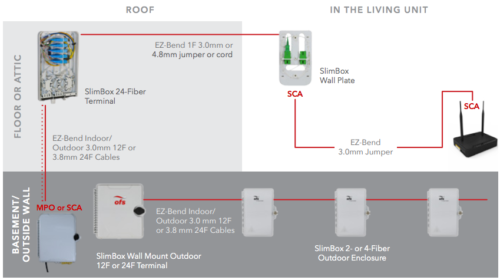

Brownfield Outdoor Facade Solution

The Outdoor Facade Solution is used when property owners want to preserve the decor of the building exterior. The compact EZ-Bend Indoor/Outdoor cable is placed vertically on the exterior wall of the residence from an outdoor wall mount box to an indoor SlimBox® unit. The indoor SlimBox can be factory configured with SCA adapters or fanouts for a pre-terminated solution, or for fusion splicing. EZ-Bend jumpers are used for the path to each living unit. Pre-terminated EZ-Bend Jumpers are recommended for faster installation, or a mechanical connector may be used for field termination in the SlimBox Wall Plate. The 80×80 InvisiLight® Module can be used as a “fiber extension” to any location in the living unit. Alternatively, instead of EZ-Bend jumpers, the InvisiLight MDU solution may be placed in the hallway to the living units (not shown).

Brownfield Outdoor Facade Solution

Greenfield Pre-Terminated Solution

TELECOMMUNICATION ROOM

- Compact basement box for a progressive customer activation;

- The basement box (SlimBox 64F Terminal) allows fusion splices for the outside plant cable;

- Ideal for buildings with low penetration rates: One splitter can be installed and the management of the customers is done through the SCA ports. A parking area permits easy connection of new customers;

- Several boxes can be connected for modular expansion. Connections between multiple SlimBoxes are possible through access openings between them.

RISER BACKBONE

- SCA pre-terminated cables for quick plug and play installation;

- EZ-Bend patch cords directly from the apartment unit may be used for small buildings.

HORIZONTAL DEPLOYMENT

- Direct deployment from the telecommunication closet to the apartment unit;

- Ideal for Greenfield installation;

- The EZ-Bend jumper is connected to an adapter installed in the SlimBox Wall Plate (inside the living unit).

INSIDE THE LIVING UNIT

- An SCA mechanical connector can be used to terminate the EZ-Bend Jumper inside the living unit;

- The InvisiLight ILU Solution is a complementary product used to extend the fiber inside the apartment.

>> DOWNLOAD OUR GUIDE NOW

Greenfield Fusion Spliced or Field Terminated Solution

TELECOMMUNICATION ROOM

- Compact basement box for a progressive customer activation (parking up to 48 connectors in the SlimBox 64F Terminal);

- The basement box (SlimBox 64F Terminal) allows fusion splices for the outside plant cable and the internal cables (up to 96 fusion splices – 8 splice trays with 12 splices in each one);

- Ideal for buildings with low penetration rate: One splitter can be installed with management of the customers done through the SCA ports. A parking area permits easy connection of new customers;

- Several boxes can be connected for modular expansion. Connections between SlimBoxes are possible through access openings between them.

RISER BACKBONE

- ACCUMAX® cables may be used for quick and easy installation:

- SCA pre-terminated pigtails are used for fusion splicing inside the basement and floor boxes.

HORIZONTAL DEPLOYMENT

- Direct deployment from the telecommunication closet to the apartment unit through EZ-Bend cable (ruggedized 3.0 or 4.8 mm);

- The horizontal cable is fusion spliced or field terminated with a mechanical connector in the SlimBox 12F Terminal (floor distribution box) and in the SlimBox Wall Plate (inside the living unit).

INSIDE THE LIVING UNIT

- An SCA mechanical connector can be used to terminate the EZ-Bend Jumper inside the living unit or a pre-terminated pigtail can be used;

- The InvisiLight ILU Solution is a complementary product used to extend the fiber inside the apartment.

>> DOWNLOAD OUR GUIDE NOW

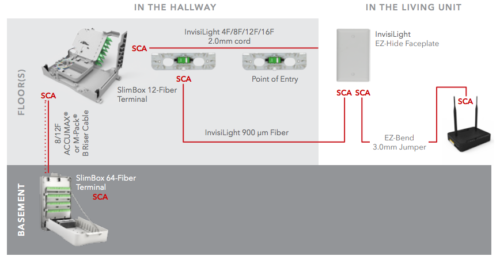

Brownfield Pre-Terminated Solution

Brownfield Pre-Terminated Solution

TELECOMMUNICATION ROOM

- Compact basement box for progressive customer activation;

- The basement box (SlimBox™ 64F Terminal) allows fusion splices to the outside plant cable;

- Ideal for buildings with low penetration rate: One splitter can be installed with management of the customers done through the SCA ports. A parking area permits easy connection of new customers;

- Boxes can be added for modular expansion. Connections between SlimBox units are easily made using jumpers through multiple ports designed into the box.

RISER BACKBONE

- SCA pre-terminated cables for quick plug and play installation:

- It is possible to place InvisiLight 2.0 mm 12-Fiber multifiber cord directly from the basement box and down hallways in small or garden style buildings.

HORIZONTAL DEPLOYMENT

- The InvisiLight MDU Point of Entry (POE) Module offers a discrete solution using field termination inside the module;

- Virtually invisible installation using the InvisiLight 12F Pre-terminated 2.0 mm cord.

INSIDE THE LIVING UNIT

- InvisiLight ILU Solution is complementary and connects to the InvisiLight MDU installation;

- InvisiLight ILU Solution is installed with the same tools and procedures as the InvisiLight MDU Solution

This 64-page guide with illustrations and part specifications will help in selecting the right fiber optic cables and accessories to reduce both the first and life cycle costs of fiber deployments to business customers inside buildings.

>> DOWNLOAD OUR GUIDE NOW

How do you make a great fiber optic solution even better? One way is to make the optical fiber less visible while also faster and easier to install.

How do you make a great fiber optic solution even better? One way is to make the optical fiber less visible while also faster and easier to install.

The new InvisiLight® Indoor Living Unit (ILU) 600 Solution from OFS is setting a new benchmark for low-profile visibility. This new solution offers fast and virtually undetectable, indoor optical fiber installation for homes, offices, and multiple living units (MDUs).

To provide Wi-Fi coverage, Fiber-to-the-Home (FTTH) and Fiber-to-the-Business (FTTB) service providers often install compact Optical Network Terminals (ONTs) deep into subscriber homes and offices. This equipment can clash with the existing décor, upsetting customers, and also create deployment issues for installers. In fact, some customers actually cancel service orders when they realize that unsightly, conventional fiber optic cables or tapes will be installed in their homes. On top of this, tight spaces, corners, architectural features, and other factors can create barriers to indoor optical fiber deployments. Fortunately, the portfolio of InvisiLight Optical Solutions was specifically designed to help meet these challenges.

Launched in 2012, the original, award-winning InvisiLight ILU Solution offers installers an innovative and simple method for indoor optical fiber installation. The process involves adhering a 0.9 mm diameter optical fiber into either crevices along ceilings and walls or moldings and walls. The result is a protected optical fiber link that is virtually invisible.

While the InvisiLight 600 ILU Solution features an even smaller 0.6 mm optical fiber, it uses the same easy installation process and tools as the original InvisiLight Solution. And, with less than half the volume and weight, the InvisiLight 80×80 Module’s storage capacity is more than doubled from 10 to 25 meters (83 feet).

All InvisiLight products, including the ILU 600 Solution, feature leading-edge OFS EZ-Bend® Optical Fiber. This fiber’s 2.5 mm minimum bend radius easily handles the sharp corners often encountered when installers conform optical fiber to a building.

In fact, in a recent field trial in Europe, an InvisiLight Solution received excellent feedback, including:

“We’re a big fan of EZ-Bend. I am amazed at some of the runs we have used it on with no apparent losses

(extreme bends, harsh pulls etc.).” – UK Service Provider

“This is the best indoor solution we have seen. Adhesive and cable are very easy to work with. Cannot

believe the low loss measured. The end customer is impressed.” – Large Ireland Network Services

Company and Ireland Service Provider

Searching for a highly-dense fiber optic cable solution with a familiar, cost-effective central core design? Then look no further than the AccuRoll® Dry Core (DC) Rollable Ribbon (RR) Fiber Optic Cable.

Searching for a highly-dense fiber optic cable solution with a familiar, cost-effective central core design? Then look no further than the AccuRoll® Dry Core (DC) Rollable Ribbon (RR) Fiber Optic Cable.

The newest member of the OFS outside plant (OSP) rollable ribbon fiber optic cable line, the AccuRoll DC RR Cable offers twice the fiber density of comparable, standard flat ribbon cables in a smaller and lighter-weight cable. And, this cable is the first and only central core rollable ribbon design that features familiar linear strength elements and a protective central core tube. This core tube delivers enhanced safety for the rollable ribbons beyond that offered by other flexible ribbon cables.

What Are Rollable Ribbons? The AccuRoll DC RR Cable features rollable ribbons, the most exciting technology breakthrough in OSP cabling in years. This technology literally doubles the density of a fiber optic cable while reducing that same cable’s size and weight.

Rollable ribbons are formed by partially bonding individual 250 micron optical fibers to each other at predetermined points. These flexible ribbons can be rolled into very tight bundles for twice the density. Inside the fiber optic cable, rollable ribbons behave much like traditional ribbons, allowing highly efficient splicing using traditional flat ribbon splicing machines and procedures. The rollable ribbons can also be easily broken out into single or multiple fibers and routed.

Why the AccuRoll DC RR Cable? As fiber counts rise, but duct space and cable storage remain at a premium, smaller, lighter weight, and more flexible rollable ribbon cables are an excellent alternative to traditional flat ribbon cable technologies.

Available with 144 to 432 fibers in both metallic and dielectric designs, there’s an AccuRoll DC RR Cable to meet the needs of your application. These fiber optic cables are an excellent choice for connecting data centers or in underground, direct buried, and lashed aerial deployments.

Think about it: doubling your network’s fiber density means doubling your transmission capacity, doubling your capability, and doubling your ability to get the job done.

Searching for an innovative fiber optic termination tool or kit? Then look no further: the FITEL EZ-Terminator tool is here.

Searching for an innovative fiber optic termination tool or kit? Then look no further: the FITEL EZ-Terminator tool is here.

The newest member of the FITEL Connectivity Solutions portfolio, the EZ-Terminator connector termination tool uses a simple, one-step operation and user-friendly interface to achieve the highest-quality terminations, quickly and under the most demanding conditions.

This handheld connector termination tool combines portability with a ruggedized body to provide the maximum accessibility and powerful performance needed for use in Multiple Dwelling Unit (MDU) and Single-Family Unit (SFU) installations. In addition, the EZ-Terminator tool’s industry-first, patented, removable V-groove allows easy cleaning and optical maintenance.

The EZ-Terminator connector termination tool is designed for use with Splice On Connector (SOC) solutions, and is essential for any termination project. This tool’s features and benefits include:

- User-Friendly Design – The wide operation chamber offers easy optical fiber loading and connector assembly;

- Simple Operation – The design allows one-touch operation and pre-installed programs for error-free SOC fiber termination projects;

- Excellent Visibility – Three LED lights illuminate the entire operating chamber with more than 300 Lux. This intense bright light is critical to performing connector terminations in low-light environments.

- Industry-First, Patented, Removable V-Groove – The industry’s only removable V-groove makes cleaning and optimal maintenance easy to achieve in only minutes and with no tools. This capability reduces downtime and supports optical performance.

Combined with a variety of EZ!Fuse™ SOC Components, the EZ-Terminator connector termination tool helps to save both time and money by delivering optical loss performance and yields that substantially surpass those of currently-available mechanical connectors. And, on top of this, the large battery capacity can achieve 100 termination/heating cycles on a single charge, providing installers with portability without sacrificing performance.

The EZ-Terminator connector termination tool’s simple, error-free operation and powerful, consistent performance make it a must-have for any fiber termination project where the highest-quality, repeatable results are critical.

And don’t forget to check out our termination tool kits

Using optical fiber networks, people can access and share information at an amazing level. They can communicate, work and learn from virtually anywhere there’s an Internet connection. For people in rural communities that lack wireless or broadband services, their ability to obtain information is clearly unequal. Even getting a signal for a cellphone or laptop can mean driving miles to a more populated area. Life is much easier with an available high-speed optical fiber network.

Using optical fiber networks, people can access and share information at an amazing level. They can communicate, work and learn from virtually anywhere there’s an Internet connection. For people in rural communities that lack wireless or broadband services, their ability to obtain information is clearly unequal. Even getting a signal for a cellphone or laptop can mean driving miles to a more populated area. Life is much easier with an available high-speed optical fiber network.

Leveling the Playing Field

Implementing optical fiber helps to “level the playing field” by providing more equal access to information and opportunities for rural residents. In reality, optical fiber and wireless services can transform rural communities.

When optical fiber arrives, one obvious plus is being able to access a cell signal from home. That wireless service requires optical fiber, which acts as the nervous system of a network. Fiber to the Tower and Fiber to the Building lay the actual groundwork for wireless communications including LTE and 4G, and soon to come 5G. The benefits of this connectivity can be seen in three distinct areas as follows.

Rural Healthcare

Digital revolution through high-speed optical fiber Internet helps medical facilities provide better treatment for patients in rural areas in a number of ways, including:

- Physicians can search files, consult with specialists and use remote diagnostics and alternative healthcare delivery methods;

- Healthcare professionals may use connected devices to directly monitor and care for patients;

- Patients practice “self-care” by accessing health-related information on the Internet.

Education

Teachers need optical fiber connectivity for video lectures and e-learning that can be widely shared. Students also need access to home Internet to complete homework and expand their learning. Colleges and universities require high-speed optical fiber Internet access to stay competitive and ensure their degree programs stay relevant.

Growth in Rural Communities

With 25% of rural residents lacking Internet access, fiber optic infrastructure build-outs are still needed. More people move into rural areas when they can maintain their standard of living. When optical fiber connectivity is optimal, existing or new businesses can reach and attract highly-qualified employees no matter where they live.

In rural areas where high-speed Internet is available, even small businesses and farms can benefit. The Internet of Things (IoT), another product of this digital revolution, makes Smart Farming possible. By applying sensing technologies through Smart Farming, farmers can practice more precise and scientific agriculture that results in increasingly bountiful, high-quality harvests.

As everyone uses more bandwidth than ever before, today’s networks require more optical fiber in less space. To help address this need, OFS introduced Fortex™ 2DT Fiber Optic Cable, the newest addition to the completely gel-free Fortex DT Cable product line.

As everyone uses more bandwidth than ever before, today’s networks require more optical fiber in less space. To help address this need, OFS introduced Fortex™ 2DT Fiber Optic Cable, the newest addition to the completely gel-free Fortex DT Cable product line.

Fiber Optic Cable: Getting Smaller and More Dense

Fortex 2DT Cable is the industry’s first fully Telcordia GR-20-rated, totally gel-free, loose tube fiber optic cable to feature 200 micron (µm) optical fiber. This fiber literally doubles the fiber count in the cable buffer tubes, significantly increasing fiber density. And, by using AllWave®+ 200 Micron ZWP Single-Mode Fiber, this fiber optic cable also offers more efficient use of network pathways.

Just as importantly, the Fortex 2DT Cable design reduces cable outer diameters by up to 18% and areas by up to 32%. This smaller outer cable diameter increases the efficient use of duct and subducts. Plus, cables with reduced outer diameters allow longer continuous cable reel lengths, which can result in fewer splices needed. In a deployment over long distances, less splicing can help create substantial cost savings.

Lighter is Better

The Fortex 2DT Cable is also lighter in weight. This lower weight can help to reduce cable pulling tensions which can increase cable pulling lengths. These increased pulling lengths can, in turn, help to save on installation time and costs. For aerial deployments, a lighter-weight cable can also decrease the loads on poles.

A Fiber Optic Cable Design for Your Application

The Fortex 2DT Cable product line features single jacket, light armor and armored cable options. These cables are available with up to 288 fibers in Telcordia GR-20 Issue 4 compliant cable designs. While the single jacket cable is an excellehttps://fiber-optic-catalog.ofsoptics.com/item/outdoor-fiber-optic-cables/loose-tube-fiber-optic-cables-1/fortex-2dt-single-jacket-cablent choice for duct, lashed aerial and general outside plant (OSP) installations, the light armor and armored cables feature a layer of rugged electrolytically chrome-coated steel (ECCS) armor. The armored cable also includes an inner polyethylene (PE) jacket. With these added features, the light armor and armored cables offer extra durable crush resistance for more demanding OSP applications, including direct buried in challenging environments.

>> View our complete line of Fiber Optic Cable

Page 1 of 712345...»Last »

A typical PON network consists of the Optical Line Terminal (OLT) in a central office, head end or

A typical PON network consists of the Optical Line Terminal (OLT) in a central office, head end or

How do you make a great fiber optic solution even better? One way is to make the optical fiber less visible while also faster and easier to install.

How do you make a great fiber optic solution even better? One way is to make the optical fiber less visible while also faster and easier to install. Searching for a highly-dense fiber optic cable solution with a familiar, cost-effective central core design? Then look no further than

Searching for a highly-dense fiber optic cable solution with a familiar, cost-effective central core design? Then look no further than  Searching for an innovative fiber optic termination tool or kit? Then look no further: the

Searching for an innovative fiber optic termination tool or kit? Then look no further: the

Using optical fiber networks, people can access and share information at an amazing level. They can communicate, work and learn from virtually anywhere there’s an Internet connection. For people in

Using optical fiber networks, people can access and share information at an amazing level. They can communicate, work and learn from virtually anywhere there’s an Internet connection. For people in  As everyone uses more bandwidth than ever before, today’s networks require more optical fiber in less space. To help address this need, OFS introduced

As everyone uses more bandwidth than ever before, today’s networks require more optical fiber in less space. To help address this need, OFS introduced