OFS will showcase its new Shape Sensor Fiber at the BIOS/Photonics West Exposition in San Francisco, January 28-February 2, 2017.

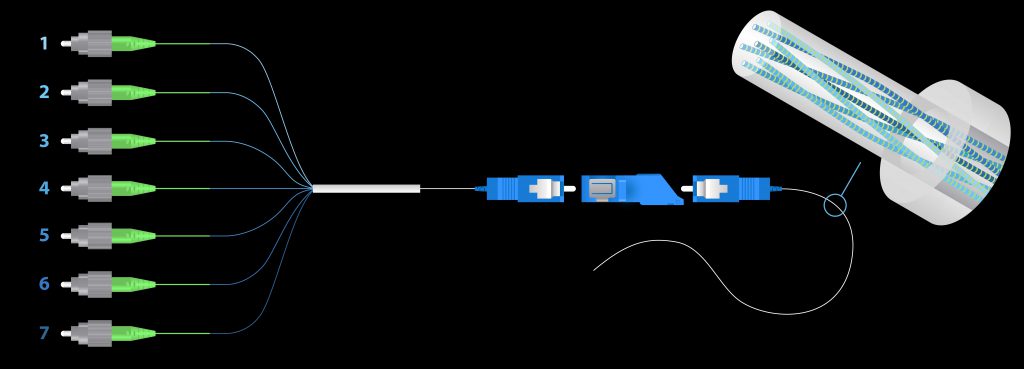

To create the Shape Sensor Fiber, OFS developed a technology platform to produce high-quality, twisted multicore optical fiber with continuous Fiber Bragg Gratings (FBGs). This type of fiber with FBGs provides stable and good signal-to-noise ratio throughout the fiber length and ease of use to customers. The manufacturing platform also allows OFS to customize and optimize the fiber to meet various customer demands more economically. In addition, OFS also offers low back reflection distal termination, multicore connectorization and fan-outs to support customer demand.

Many medical device companies are developing cutting-edge endoscopes, catheters and other equipment with shape sensing technology to increase the quality of patient care. By embedding or surface-attaching the fiber to surgical tools or other devices, technicians can calculate and reconstruct the 3D shape of an instrument on a display screen. By allowing users to monitor the exact shape and position of the instrument, physicians can conduct minimally invasive surgery (MIS) or treatment which generally results in shorter recovery times, less pain and trauma, reduced rates of infection and shorter hospital stays.

Learn more about OFS Fiber Optic Sensors