Understanding Optical Fiber Specifications

This article in our technical series will focus on single-mode optical fiber geometries.

If you subscribed to our Light Post Emails, you know we previously covered bandwidth demand drivers and introductory standards as well as fiber optic dispersion. In this article, we’ll work our way through a typical fiber specification, highlighting the importance of various single-mode optical fiber geometry specifications.

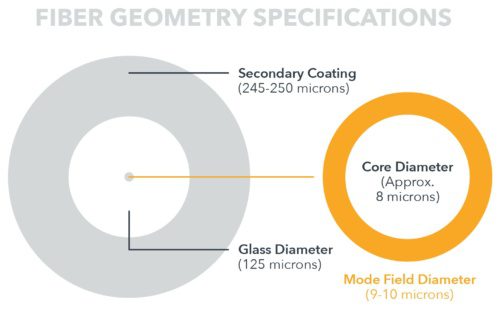

Cladding (Glass) Diameter – 125.0 ± 0.7 µm

Cladding diameter is the outer diameter of the glass portion of the optical fiber. For telecommunications fibers, this diameter has been 125 microns (µm) for a very long time. On the other hand, the diameter tolerance has not always been 0.7 µm.

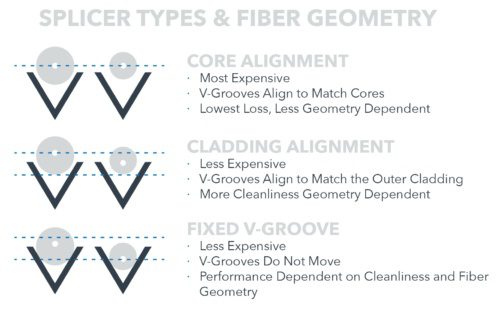

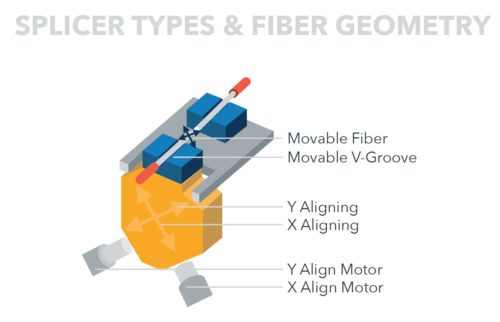

During the 1980s, optical fibers had outer diameter tolerances as high as +/- 3.0 µm. As you can imagine, matching up fiber cores ranging from 122 to 128 µm in diameter could result in extremely high loss. This situation is why fusion splicing machines required additional technology to help align the fiber cores. This extra technology increased the price of the splicing units.

Mode Field Diameter (MFD)

Mode field diameter (MFD) is another specification related to fiber geometry. In a typical G.652.D compliant single-mode optical fiber, not all of the light travels in the core; in fact, a small amount of light travels in the fiber cladding. The term MFD is a measure of the diameter of the optical power density distribution, which is the diameter in which 95% of the power resides.

Clad Non-Circularity of d 0.7 %

Clad non-circularity measures a fiber’s deviation from perfectly round, and is measured as a percentage difference versus perfect.

Core/Clad Concentricity Error (Offset) of d 0.5 ¼m, < 0.2 ¼m typically

Core/clad concentricity error (CCCE) measures how well the core is centered in the fiber. CCCE is measured in microns and, of course, the closer the core is placed to perfect center, the better it is.

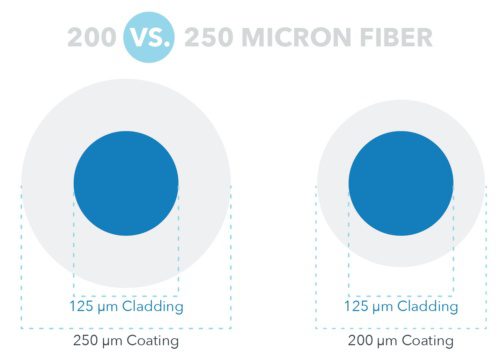

Although the difference between 200 and 250 µm is not tremendously large, smaller diameter fibers can enable twice the fiber count in the same size buffer tube, while also still preserving long-term reliability.

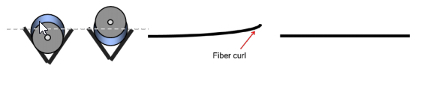

Fiber Curl

Fiber curl assesses the non-linearity of bare glass. In other words, fiber curl measures how straight the glass fiber is when no external stressors are present. If imbalanced stresses are frozen into a fiber during the draw process, curl can result. This curl can show up during the splicing of fiber optic ribbons or when fixed V-groove splicing machines are used.

In closing, fiber geekdom is a journey, not a destination, and there’s always more to learn. OFS has multiple decades of experience with fiber-optic cable networks. Please contact your local OFS representative if you would like additional information regarding optical fiber geometry specifications.

Tags: single-mode fiber