How do you make a great fiber optic solution even better? One way is to make the optical fiber less visible while also faster and easier to install.

How do you make a great fiber optic solution even better? One way is to make the optical fiber less visible while also faster and easier to install.

The new InvisiLight® Indoor Living Unit (ILU) 600 Solution from OFS is setting a new benchmark for low-profile visibility. This new solution offers fast and virtually undetectable, indoor optical fiber installation for homes, offices, and multiple living units (MDUs).

To provide Wi-Fi coverage, Fiber-to-the-Home (FTTH) and Fiber-to-the-Business (FTTB) service providers often install compact Optical Network Terminals (ONTs) deep into subscriber homes and offices. This equipment can clash with the existing décor, upsetting customers, and also create deployment issues for installers. In fact, some customers actually cancel service orders when they realize that unsightly, conventional fiber optic cables or tapes will be installed in their homes. On top of this, tight spaces, corners, architectural features, and other factors can create barriers to indoor optical fiber deployments. Fortunately, the portfolio of InvisiLight Optical Solutions was specifically designed to help meet these challenges.

Launched in 2012, the original, award-winning InvisiLight ILU Solution offers installers an innovative and simple method for indoor optical fiber installation. The process involves adhering a 0.9 mm diameter optical fiber into either crevices along ceilings and walls or moldings and walls. The result is a protected optical fiber link that is virtually invisible.

While the InvisiLight 600 ILU Solution features an even smaller 0.6 mm optical fiber, it uses the same easy installation process and tools as the original InvisiLight Solution. And, with less than half the volume and weight, the InvisiLight 80×80 Module’s storage capacity is more than doubled from 10 to 25 meters (83 feet).

All InvisiLight products, including the ILU 600 Solution, feature leading-edge OFS EZ-Bend® Optical Fiber. This fiber’s 2.5 mm minimum bend radius easily handles the sharp corners often encountered when installers conform optical fiber to a building.

In fact, in a recent field trial in Europe, an InvisiLight Solution received excellent feedback, including:

“We’re a big fan of EZ-Bend. I am amazed at some of the runs we have used it on with no apparent losses

(extreme bends, harsh pulls etc.).” – UK Service Provider

“This is the best indoor solution we have seen. Adhesive and cable are very easy to work with. Cannot

believe the low loss measured. The end customer is impressed.” – Large Ireland Network Services

Company and Ireland Service Provider

Searching for a highly-dense fiber optic cable solution with a familiar, cost-effective central core design? Then look no further than the AccuRoll® Dry Core (DC) Rollable Ribbon (RR) Fiber Optic Cable.

Searching for a highly-dense fiber optic cable solution with a familiar, cost-effective central core design? Then look no further than the AccuRoll® Dry Core (DC) Rollable Ribbon (RR) Fiber Optic Cable.

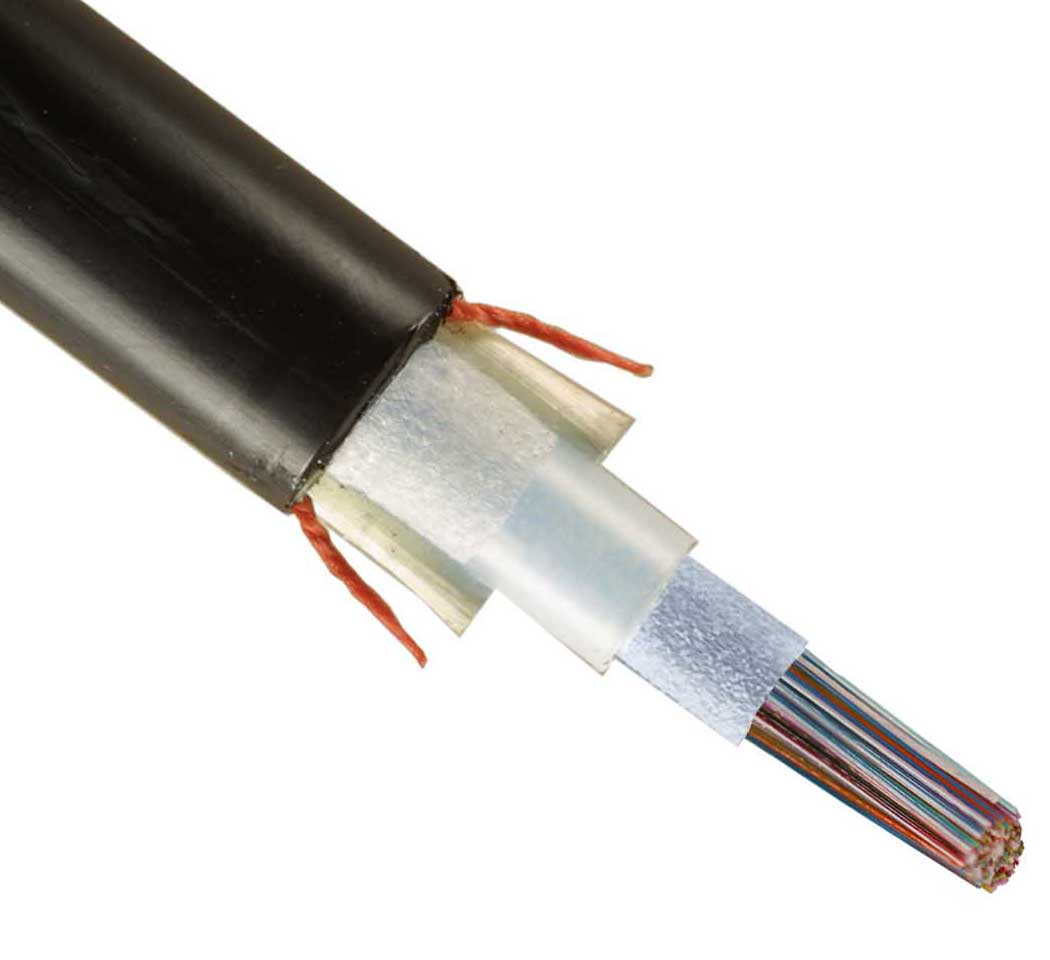

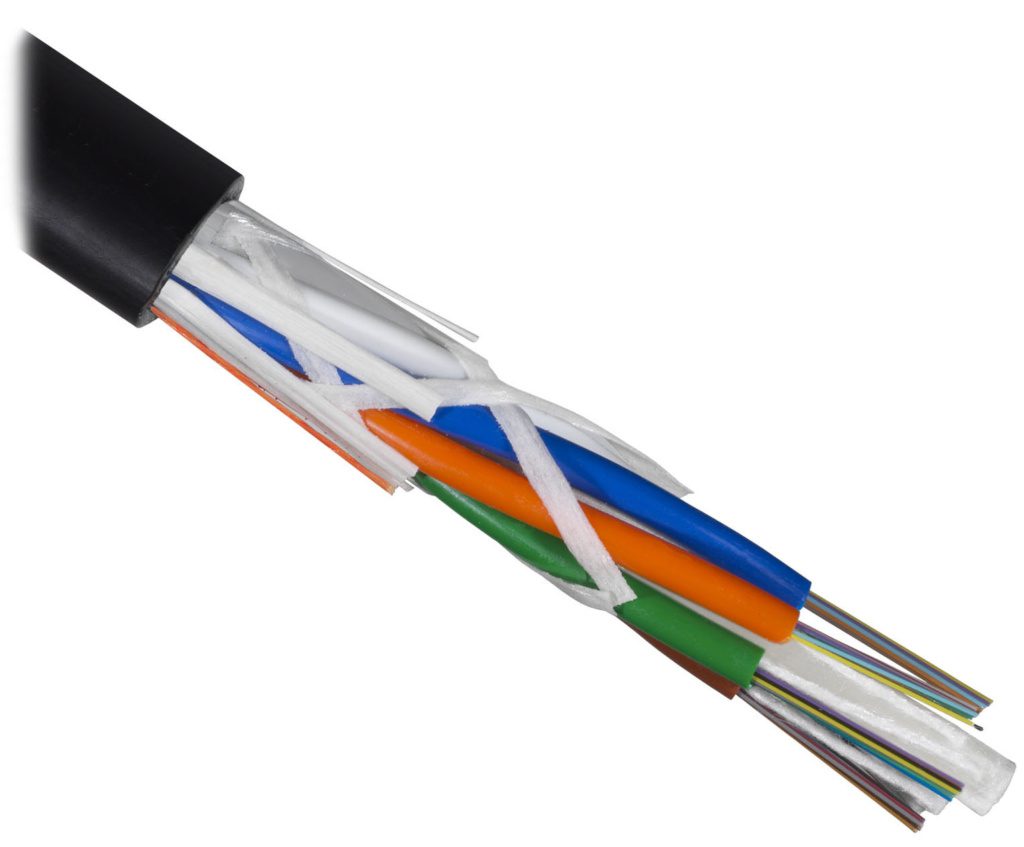

The newest member of the OFS outside plant (OSP) rollable ribbon fiber optic cable line, the AccuRoll DC RR Cable offers twice the fiber density of comparable, standard flat ribbon cables in a smaller and lighter-weight cable. And, this cable is the first and only central core rollable ribbon design that features familiar linear strength elements and a protective central core tube. This core tube delivers enhanced safety for the rollable ribbons beyond that offered by other flexible ribbon cables.

What Are Rollable Ribbons? The AccuRoll DC RR Cable features rollable ribbons, the most exciting technology breakthrough in OSP cabling in years. This technology literally doubles the density of a fiber optic cable while reducing that same cable’s size and weight.

Rollable ribbons are formed by partially bonding individual 250 micron optical fibers to each other at predetermined points. These flexible ribbons can be rolled into very tight bundles for twice the density. Inside the fiber optic cable, rollable ribbons behave much like traditional ribbons, allowing highly efficient splicing using traditional flat ribbon splicing machines and procedures. The rollable ribbons can also be easily broken out into single or multiple fibers and routed.

Why the AccuRoll DC RR Cable? As fiber counts rise, but duct space and cable storage remain at a premium, smaller, lighter weight, and more flexible rollable ribbon cables are an excellent alternative to traditional flat ribbon cable technologies.

Available with 144 to 432 fibers in both metallic and dielectric designs, there’s an AccuRoll DC RR Cable to meet the needs of your application. These fiber optic cables are an excellent choice for connecting data centers or in underground, direct buried, and lashed aerial deployments.

Think about it: doubling your network’s fiber density means doubling your transmission capacity, doubling your capability, and doubling your ability to get the job done.

Searching for an innovative fiber optic termination tool or kit? Then look no further: the FITEL EZ-Terminator tool is here.

Searching for an innovative fiber optic termination tool or kit? Then look no further: the FITEL EZ-Terminator tool is here.

The newest member of the FITEL Connectivity Solutions portfolio, the EZ-Terminator connector termination tool uses a simple, one-step operation and user-friendly interface to achieve the highest-quality terminations, quickly and under the most demanding conditions.

This handheld connector termination tool combines portability with a ruggedized body to provide the maximum accessibility and powerful performance needed for use in Multiple Dwelling Unit (MDU) and Single-Family Unit (SFU) installations. In addition, the EZ-Terminator tool’s industry-first, patented, removable V-groove allows easy cleaning and optical maintenance.

The EZ-Terminator connector termination tool is designed for use with Splice On Connector (SOC) solutions, and is essential for any termination project. This tool’s features and benefits include:

- User-Friendly Design – The wide operation chamber offers easy optical fiber loading and connector assembly;

- Simple Operation – The design allows one-touch operation and pre-installed programs for error-free SOC fiber termination projects;

- Excellent Visibility – Three LED lights illuminate the entire operating chamber with more than 300 Lux. This intense bright light is critical to performing connector terminations in low-light environments.

- Industry-First, Patented, Removable V-Groove – The industry’s only removable V-groove makes cleaning and optimal maintenance easy to achieve in only minutes and with no tools. This capability reduces downtime and supports optical performance.

Combined with a variety of EZ!Fuse™ SOC Components, the EZ-Terminator connector termination tool helps to save both time and money by delivering optical loss performance and yields that substantially surpass those of currently-available mechanical connectors. And, on top of this, the large battery capacity can achieve 100 termination/heating cycles on a single charge, providing installers with portability without sacrificing performance.

The EZ-Terminator connector termination tool’s simple, error-free operation and powerful, consistent performance make it a must-have for any fiber termination project where the highest-quality, repeatable results are critical.

And don’t forget to check out our termination tool kits

Fiber to the Home (FTTH) is becoming increasingly more common as bandwidth usage is exploding. This tremendous growth is driven in part by the rapid increase in Internet-connected devices and the use of data-heavy applications such as video on demand. Service providers are working to meet this need for greater bandwidth by expanding the deployment of fiber optic cables to the premises and then into the home.

Service providers building these fiber networks all face a common challenge: the expense of the last mile in the optical network. It is critical for service providers, utilities and municipalities to have an optimized set of deployment options that help to reduce both capital and operational expenses.

The solutions presented in this article meet these challenges with several fiber deployment options from the drop point to and into the home.

OFS FTTx Solutions for the Home can help residents take advantage of the Internet of Things (IoT), which is beginning to redefine how we work and live. These solutions focus on simplicity, cost-effectiveness and speed of installation, along with the pre- and post-installation customer experience, time to revenue generation and reliable subscriber connections that help to improve profitability for the service provider.

FTTH is considered the best technology to handle consumer network demands in the future because of its high bandwidth.

>> Download the Full Guide Now

PRE-TERMINATED vs. FIELD-TERMINATED DROPS

Pre-terminated drop solutions are increasingly used to install fiber to homes to save time and money in higher labor cost regions. Pre-terminated drop solutions consist of drop cables that are terminated and tested in the factory, and easily plugged into the drop terminal and home terminal in the field. Pre-terminated solutions offer lower costs and faster deployment and require less installation skill.

For low labor cost markets, field terminated solutions may be preferred. Field terminated solutions use drop cables which are terminated using fusion splicing or mechanical connectors in the field during installation. They offer easier inventory management, lower material costs and easier slack management, but take longer to install and require more highly skilled labor, along with expensive field termination tools and splicing machines, when compared to pre-terminated solutions.

A third approach, with one end of the drop cable pre-terminated, and the other end field terminated, can solve the slack issue and allow an easy plug-in to the drop terminal and field termination at the home.

OFS offers all three of these drop solution options to fit the unique needs of each service provider. OFS pre-terminated solutions are available with EZ- Bend® cables that can solve the slack management challenge. EZ-Bend fiber optic cables enable the slack to be tied into a very compact bundle.

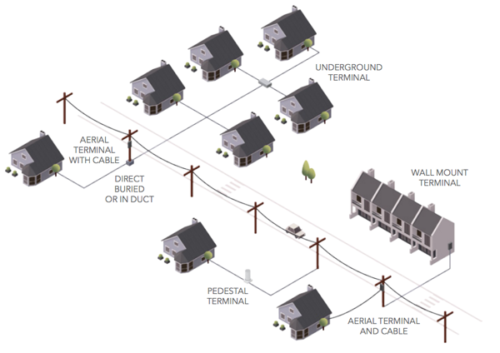

Providers typically use a combination of aerial and underground solutions to connect the last mile in a network to individual homes. A variety of factors including climate and existing infrastructure can influence solution selection.

>> Download the Full Guide Now

CONNECTING OPTICAL FIBER TO THE HOME

OFS offers a complete portfolio of aerial and underground solutions including terminals, integrated splitters and drop cables to connect to the demarcation point of individual homes. From that location, a number of solutions can be leveraged to take optical fiber into the home.

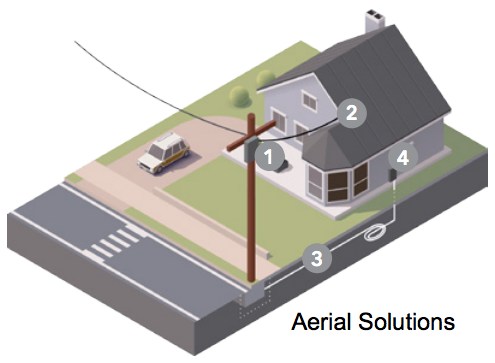

Aerial deployment is typically lower in cost and preferred where poles are in place near homes. In this scenario, a SlimBox® Drop Terminal is installed on a pole, with or without splitters, and then connected by a drop cable to as many as 16 homes. Below grade drop deployment is preferred if there is an existing duct placed from the terminal location to the home, or if below grade cabling is required by local regulations.

Aerial deployment is typically lower in cost and preferred where poles are in place near homes. In this scenario, a SlimBox® Drop Terminal is installed on a pole, with or without splitters, and then connected by a drop cable to as many as 16 homes. Below grade drop deployment is preferred if there is an existing duct placed from the terminal location to the home, or if below grade cabling is required by local regulations.

First, an installer inserts a feeder or distribution cable into the terminal. The installer then extracts the number of fibers required and fusion splices them to a pre-terminated splitter or drop fiber. Aerial or underground drop cables are then deployed from the terminal to individual residences.

In the case of aerial cables, a drop cable is placed between the pole and a point near a home’s roof. The cable can be connected to a demarcation box and installed into the home through the attic or onto the side of the house at a demarcation box near the ground. To help avoid unsightly aerial cables, an aerial terminal can be connected to an underground drop cable. For aerial deployments, OFS offers the one to 24-fiber Mini LT Flat Drop Cable and the single-fiber Mini TB Flat Drop cable which contains 3 mm cordage that can be routed directly to an Optical Network Terminal (ONT).

>> Download the Full Guide Now

Underground drop cable options include the single-fiber EZ-Bend® 3.0 mm and 4.8 mm Ruggedized Cables and EZ-Bend Toneable Cables. The toneable cables enable easy above ground locating of buried cables to help avoid cable cuts when other underground systems are installed. These drop cables are installed from the aerial terminal down the pole to the ground, and are then buried to minimize disruption to landscaping, or pulled into existing duct. The cable is then connected into a demarcation box installed at the side of the house, ideally in a location close to the ONT on the inside.

Underground drop cable options include the single-fiber EZ-Bend® 3.0 mm and 4.8 mm Ruggedized Cables and EZ-Bend Toneable Cables. The toneable cables enable easy above ground locating of buried cables to help avoid cable cuts when other underground systems are installed. These drop cables are installed from the aerial terminal down the pole to the ground, and are then buried to minimize disruption to landscaping, or pulled into existing duct. The cable is then connected into a demarcation box installed at the side of the house, ideally in a location close to the ONT on the inside.

EZ-Bend cables are preferred since their 2.5 mm bend radius allows the cables to be coiled, bent and tied without creating signal degradation. These cables can also be buried or stapled/clipped and bent around the outer perimeter walls of a home to reach an entry point closer to the preferred ONT location.

New home construction offers a win-win situation for construction companies and service providers. With the ability to “build in” optical fiber connectivity, new homes are futureproofed from the beginning, real estate values increase, and new home owners can become immediate subscribers without the expense of additional installation time. .

Subscribers can be connected faster using preterminated cables installed to and into homes during construction. OFS offers EZ-Bend 3.0 mm and 4.8 mm cables that can be installed independently or in ducts using typical home wiring techniques, such as stapling or zip-tying of the cables, to a location or media panel where the ONT would be later placed. The home owner can later perform a “self install” by receiving an ONT from the service provider, and simply plugging in an EZ-Bend cable assembly and a power adapter to the ONT. OFS also provides a SlimBox Wall Plate that discretely blends into a home’s décor and facilitates ONT connections in the same way as a power outlet.

Existing Homes can pose a challenge to network installers, given the wide variety of possible building architectures. In addition, home designs and construction materials can vary greatly from country to country and even within countries. OFS solutions are purposefully designed and optimized to suit a variety of homes globally and offer maximum flexibility to on-site installers.

Depending on the target market, a provider can choose the terminals and drop cables for an aerial, underground or hybrid solution. The solutions described are the most popular options and feature a variety of products as building block components. This modular product design approach allows service providers to also create custom solutions to meet the specific needs of their target markets.

>> Download the Full Guide Now

Seismologists from the California Institute of Technology (Caltech) are using fiber optic network cable to monitor and record aftershocks from the July 4 and 5 Ridgecrest, CA, earthquakes. By using optical fiber, the scientists can gather, track, and analyze data in much greater depth from the thousands of daily aftershocks.

Seismologists from the California Institute of Technology (Caltech) are using fiber optic network cable to monitor and record aftershocks from the July 4 and 5 Ridgecrest, CA, earthquakes. By using optical fiber, the scientists can gather, track, and analyze data in much greater depth from the thousands of daily aftershocks.

To do this, the scientists send a beam of light down optical fiber in an unused or “dark” fiber optic cable. When the light reaches tiny blemishes in the optical fiber, a small portion of the light is reflected back and recorded. In this way, each fiber imperfection acts as a trackable location along the buried fiber optic cable. When seismic waves move through the ground, the cable expands and contracts slightly. This change affects the travel time of light to and from the locations. By monitoring these changes, seismologists can monitor the motion of seismic waves.

According to Caltech, the miniscule fiber imperfections occur often enough so that every few meters of optical fiber act as an individual seismometer. In fact, monitoring 50 kilometers of fiber optic cable in three different locations is roughly equal to deploying more than 6,000 seismometers in the area.

Caltech launched the project within days of the two large earthquakes and began contacting groups in a search for unused fiber optic cable that would be close enough and long enough to be useful. The scientists finally contacted the California Broadband Cooperative’s Digital 395 project. The goal of the Digital 395 project is to build a new 583-mile fiber optic network that will run north to south, along the eastern Sierra Nevada, passing near Ridgecrest. Digital 395 offered three segments of its fiber cable to which Caltech connected sensing instruments.

Information gathered from the Ridgecrest fiber network will help seismologists learn more about the way that earthquakes move through the earth, and specifically how seismic waves move through the area around Ridgecrest.

Single Mode vs Multimode Fibers

Learn the differences and when to use single-mode vs multimode fiber.

Cloud computing and web services continue to drive increased bandwidth demand, pushing data communications rates from 1 and 10G to 40 and 100G and beyond in enterprise and data center networks.

These higher speeds might lead system designers to believe that single-mode optical fiber enjoys an increasing advantage over multimode optical fiber in premises applications. However, higher Ethernet speeds do not automatically mean that single-mode optical fiber is the right choice.

Although single-mode optical fiber holds advantages in terms of bandwidth and reach for longer distances, multimode optical fiber easily supports most distances required for enterprise and data center networks, at a cost significantly less than single-mode.

> Download the Full Article

Total Cost Comparison of Single Mode vs Multimode Fibers

Multimode optical fiber continues to be the more cost-effective choice over single-mode optical fiber for shorter-reach applications. While the actual cost of multimode cable is greater than that of single-mode fiber optic cable, it is the optics that dominate the total cost of a network system, dwarfing variation in cable costs.

On average, single-mode transceivers continue to cost from 1.5 to 4 – 5 times more than multimode transceivers, depending on the data rate. As faster optoelectronic technology matures and volumes increase, prices come down for both, and the cost gap between multimode and single-mode decreases. However, single-mode optics have always been more expensive than their equivalent multimode counterparts. This fact is supported by the difference in multimode vs. single-mode 10G optics, a common Ethernet speed used today.

Multimode transceivers also consume less power than single-mode transceivers, an important consideration especially when assessing the cost of powering and cooling a data center. In a large data center with thousands of links, a multimode solution can provide substantial cost savings, from both a transceiver and power/cooling perspective.

Multimode transceivers also consume less power than single-mode transceivers, an important consideration especially when assessing the cost of powering and cooling a data center. In a large data center with thousands of links, a multimode solution can provide substantial cost savings, from both a transceiver and power/cooling perspective.

Finally, the fact that multimode optical fiber is easier to install and terminate in the field is an important consideration for enterprise environments, with their frequent moves, adds and changes.

The Difference Between Multimode and Single-Mode Fibers

The way in which these two fiber types transmit light eventually led to their separate names. Generally designed for systems of moderate to long distance (e.g., metro, access and long-haul networks), single-mode optical fibers have a small core size (< 10 µm) that permits only one mode or ray of light to be transmitted. This tiny core requires precision alignment to inject light from the transceiver into the core, significantly driving up transceiver costs.

In comparison, multimode optical fibers have larger cores that guide many modes simultaneously. The larger core makes it much easier to capture light from a transceiver, allowing source costs to be controlled. Similarly, multimode connectors cost less than single-mode connectors as a result of the more stringent alignment requirements of single-mode optical fiber. Single-mode connections require greater care and skill to terminate, which is why components are often pre-terminated at the factory. On the other hand, multimode connections can be easily performed in the field, offering installation flexibility, cost savings and peace of mind.

For these reasons, multimode optical fiber systems continue to be the most cost-effective fiber choice for enterprise and data center applications up to the 500 – 600 meter range.

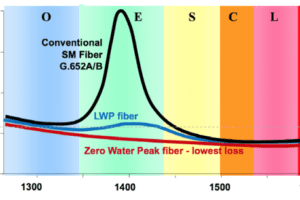

Beyond the reach of multimode optical fibers, it becomes necessary to use single-mode optical fiber. However, when assessing single-mode optical fibers, be sure to consider newer options. A bend-insensitive, full-spectrum single-mode optical fiber provides more transceiver options, greater bandwidth and is less sensitive to handling of the cables and patch cords than is conventional single-mode optical fiber.

Beyond the reach of multimode optical fibers, it becomes necessary to use single-mode optical fiber. However, when assessing single-mode optical fibers, be sure to consider newer options. A bend-insensitive, full-spectrum single-mode optical fiber provides more transceiver options, greater bandwidth and is less sensitive to handling of the cables and patch cords than is conventional single-mode optical fiber.

> Download the Full Article

Which Multimode Fiber Type and Why?

At one time, the network designer or end user who specified multimode optical fiber for short reach systems had to choose from two fiber types defined by their core size, namely, 50 micron (µm) or 62.5 µm. Now, that choice is slightly different: choose from OM3, OM4, or the new OM5 grade of 50 µm multimode optical fibers. Today, 62.5 µm OM1 multimode optical fiber is virtually obsolete and is relegated for use with extensions or repairs of legacy, low bandwidth systems. In fact, 62.5 µm OM1 fiber supports only 33 meters at 10G and is not even recognized as an option for faster speeds.

50 µm multimode optical fibers were first deployed in the 1970s for both short and long reach applications. But as data rates increased, 50 µm fiber’s reach became limited with the LED light sources used at the time. To resolve this, 62.5 µm multimode optical fiber was developed and introduced in the 1980s. With its larger core, 62.5 µm optical fiber coupled more signal power than 50 µm optical fiber, allowing for longer reach (2 kms) at 10 Mb/s to support campus applications. That was the only time when 62.5 µm fiber offered an advantage over 50 µm optical fiber.

50 µm multimode optical fibers were first deployed in the 1970s for both short and long reach applications. But as data rates increased, 50 µm fiber’s reach became limited with the LED light sources used at the time. To resolve this, 62.5 µm multimode optical fiber was developed and introduced in the 1980s. With its larger core, 62.5 µm optical fiber coupled more signal power than 50 µm optical fiber, allowing for longer reach (2 kms) at 10 Mb/s to support campus applications. That was the only time when 62.5 µm fiber offered an advantage over 50 µm optical fiber.

With the advent of gigabit (1 Gb/s) speeds and the introduction of the 850 nm VCSEL laser light source in the mid-1990s, we saw a shift back to 50 µm optical fiber, with its inherently higher bandwidth. Today, 50 µm laser-optimized multimode (OM3, OM4, and OM5) optical fibers offer significant bandwidth and reach advantages for short reach applications, while preserving the low system cost advantages of multimode optical fiber.

Planning for the Future

Industry standards groups including IEEE (Ethernet), INCITS (Fibre Channel), TIA, ISO/IEC and others continue to include multimode optical fiber as the short reach solution for next generation speeds. This designation reinforces multimode optical fiber’s continued economic advantage for these applications.

Industry standards groups including IEEE (Ethernet), INCITS (Fibre Channel), TIA, ISO/IEC and others continue to include multimode optical fiber as the short reach solution for next generation speeds. This designation reinforces multimode optical fiber’s continued economic advantage for these applications.

IEEE includes multimode optical fiber in its 40G and 100G Ethernet standards as well as its pending 50G, 200G, and 400G standards. In addition, TIA issued a new standard for the next generation of multimode optical fiber called wide band (OM5) multimode optical fiber. This new version of 50 µm optical fiber can transmit multiple wavelengths using Short Wavelength Division Multiplexing (SWDM) technology, while maintaining OM4 backward compatibility. In this way, end users can obtain greater bandwidth and higher speeds from a single fiber by simply adding wavelengths. The OFS version of this fiber is called LaserWave® WideBand Optical Fiber. This new fiber allows for continued economic benefit in deploying short reach optics using multimode optical fiber – as opposed to more expensive single-mode optics.

In Conclusion

In general, multimode optical fiber continues to be the most cost-effective choice for enterprise and data center applications up to the 500 – 600 meter range. Beyond that, single-mode optical fiber is necessary.

>> Download the Full Article to Learn More about the Difference between Multimode or Single-Mode Optical Fibers

Using optical fiber networks, people can access and share information at an amazing level. They can communicate, work and learn from virtually anywhere there’s an Internet connection. For people in rural communities that lack wireless or broadband services, their ability to obtain information is clearly unequal. Even getting a signal for a cellphone or laptop can mean driving miles to a more populated area. Life is much easier with an available high-speed optical fiber network.

Using optical fiber networks, people can access and share information at an amazing level. They can communicate, work and learn from virtually anywhere there’s an Internet connection. For people in rural communities that lack wireless or broadband services, their ability to obtain information is clearly unequal. Even getting a signal for a cellphone or laptop can mean driving miles to a more populated area. Life is much easier with an available high-speed optical fiber network.

Leveling the Playing Field

Implementing optical fiber helps to “level the playing field” by providing more equal access to information and opportunities for rural residents. In reality, optical fiber and wireless services can transform rural communities.

When optical fiber arrives, one obvious plus is being able to access a cell signal from home. That wireless service requires optical fiber, which acts as the nervous system of a network. Fiber to the Tower and Fiber to the Building lay the actual groundwork for wireless communications including LTE and 4G, and soon to come 5G. The benefits of this connectivity can be seen in three distinct areas as follows.

Rural Healthcare

Digital revolution through high-speed optical fiber Internet helps medical facilities provide better treatment for patients in rural areas in a number of ways, including:

- Physicians can search files, consult with specialists and use remote diagnostics and alternative healthcare delivery methods;

- Healthcare professionals may use connected devices to directly monitor and care for patients;

- Patients practice “self-care” by accessing health-related information on the Internet.

Education

Teachers need optical fiber connectivity for video lectures and e-learning that can be widely shared. Students also need access to home Internet to complete homework and expand their learning. Colleges and universities require high-speed optical fiber Internet access to stay competitive and ensure their degree programs stay relevant.

Growth in Rural Communities

With 25% of rural residents lacking Internet access, fiber optic infrastructure build-outs are still needed. More people move into rural areas when they can maintain their standard of living. When optical fiber connectivity is optimal, existing or new businesses can reach and attract highly-qualified employees no matter where they live.

In rural areas where high-speed Internet is available, even small businesses and farms can benefit. The Internet of Things (IoT), another product of this digital revolution, makes Smart Farming possible. By applying sensing technologies through Smart Farming, farmers can practice more precise and scientific agriculture that results in increasingly bountiful, high-quality harvests.

As everyone uses more bandwidth than ever before, today’s networks require more optical fiber in less space. To help address this need, OFS introduced Fortex™ 2DT Fiber Optic Cable, the newest addition to the completely gel-free Fortex DT Cable product line.

As everyone uses more bandwidth than ever before, today’s networks require more optical fiber in less space. To help address this need, OFS introduced Fortex™ 2DT Fiber Optic Cable, the newest addition to the completely gel-free Fortex DT Cable product line.

Fiber Optic Cable: Getting Smaller and More Dense

Fortex 2DT Cable is the industry’s first fully Telcordia GR-20-rated, totally gel-free, loose tube fiber optic cable to feature 200 micron (µm) optical fiber. This fiber literally doubles the fiber count in the cable buffer tubes, significantly increasing fiber density. And, by using AllWave®+ 200 Micron ZWP Single-Mode Fiber, this fiber optic cable also offers more efficient use of network pathways.

Just as importantly, the Fortex 2DT Cable design reduces cable outer diameters by up to 18% and areas by up to 32%. This smaller outer cable diameter increases the efficient use of duct and subducts. Plus, cables with reduced outer diameters allow longer continuous cable reel lengths, which can result in fewer splices needed. In a deployment over long distances, less splicing can help create substantial cost savings.

Lighter is Better

The Fortex 2DT Cable is also lighter in weight. This lower weight can help to reduce cable pulling tensions which can increase cable pulling lengths. These increased pulling lengths can, in turn, help to save on installation time and costs. For aerial deployments, a lighter-weight cable can also decrease the loads on poles.

A Fiber Optic Cable Design for Your Application

The Fortex 2DT Cable product line features single jacket, light armor and armored cable options. These cables are available with up to 288 fibers in Telcordia GR-20 Issue 4 compliant cable designs. While the single jacket cable is an excellehttps://fiber-optic-catalog.ofsoptics.com/item/outdoor-fiber-optic-cables/loose-tube-fiber-optic-cables-1/fortex-2dt-single-jacket-cablent choice for duct, lashed aerial and general outside plant (OSP) installations, the light armor and armored cables feature a layer of rugged electrolytically chrome-coated steel (ECCS) armor. The armored cable also includes an inner polyethylene (PE) jacket. With these added features, the light armor and armored cables offer extra durable crush resistance for more demanding OSP applications, including direct buried in challenging environments.

>> View our complete line of Fiber Optic Cable

A huge increase in digital devices, cloud computing and web services have helped fuel the tremendous demand for increased bandwidth while also pushing datacom rates to 100G and beyond. With these faster speeds and greater use, system designers might assume that single-mode optical fiber holds a growing advantage over multimode optical fiber for premises applications. However, it’s critical to remember that increased Ethernet speeds don’t necessarily mean that single-mode fiber is the best choice.

While it’s true that single-mode fiber holds bandwidth and reach advantages, especially for longer distances, multimode fiber easily supports most distances needed by data center and enterprise networks, and at a significant cost savings over single-mode fiber.

What’s the Difference?

These two optical fiber types were primarily named for the different ways that they transmit light. Single-Mode optical fibers have a small core size (less than 10 microns) and allow only one mode or ray of light to be transmitted. These fibers were mainly designed for networks that involve medium to long distances, such as metro, access and long-haul networks.

On the other hand, multimode fibers have larger cores that work to guide many modes at the same time. These larger cores make it much easier to capture light from a transceiver, helping to control source costs.

View our Single Mode vs. Multimode Fiber Guide

WHICH Multimode Fiber?

Today, network designers and end users can choose from OM3, OM4 or OM5 grades of 50 micron multimode fibers. At one time in the 1980s, as data rates increased, 62.5 micron fiber was introduced because it allowed for longer reach to support campus applications. However, with the advent of gigabit speeds, users moved back to 50 micron fiber with its inherently higher bandwidth. Now 50 micron laser-optimized multimode OM3, OM4 and OM5 fibers offer major bandwidth and reach advantages for short-reach applications along with low system costs.

The Future

Industry standards groups such as IEEE (Ethernet), TIA, ISO/IEC and others continue to recognize multimode optical fiber as the short-reach solution for next-generation speeds. In fact, TIA issued a new standard for the next generation of multimode fiber called wide band (OM5) multimode fiber. This new version of 50 micron fiber can transmit multiple wavelengths using Short Wavelength Division Multiplexing (SWDM) technology, while maintaining OM4 backward compatibility. This capability lets end users gain greater bandwidth and higher speeds from a single fiber by simply adding wavelengths. The OFS version of this fiber is LaserWave® WideBand (OM5) Optical Fiber.

In Short…

Generally, 50 micron optical fiber continues to be the most cost-effective choice for enterprise and data center use up to the 500-600 meter range. Beyond that distance, single-mode optical fiber is necessary.

The OFS LaserWave FLEX Multimode Optical Fiber family offers full performance range and has better optical and geometric specifications than standards require. However, if the network’s transmission distance requires the use of single-mode optical fiber, consider bend-insensitive, zero water peak (ZWP) full-spectrum fibers such as the OFS family of AllWave® Optical Fibers.

Page 4 of 10« First«...23456...10...»Last »

How do you make a great fiber optic solution even better? One way is to make the optical fiber less visible while also faster and easier to install.

How do you make a great fiber optic solution even better? One way is to make the optical fiber less visible while also faster and easier to install.

Searching for a highly-dense fiber optic cable solution with a familiar, cost-effective central core design? Then look no further than

Searching for a highly-dense fiber optic cable solution with a familiar, cost-effective central core design? Then look no further than  Searching for an innovative fiber optic termination tool or kit? Then look no further: the

Searching for an innovative fiber optic termination tool or kit? Then look no further: the

Aerial deployment is typically lower in cost and preferred where poles are in place near homes. In this scenario, a SlimBox® Drop Terminal is installed on a pole, with or without splitters, and then connected by a drop cable to as many as 16 homes. Below grade drop deployment is preferred if there is an existing duct placed from the terminal location to the home, or if below grade cabling is required by local regulations.

Aerial deployment is typically lower in cost and preferred where poles are in place near homes. In this scenario, a SlimBox® Drop Terminal is installed on a pole, with or without splitters, and then connected by a drop cable to as many as 16 homes. Below grade drop deployment is preferred if there is an existing duct placed from the terminal location to the home, or if below grade cabling is required by local regulations. Underground drop cable options include the single-fiber EZ-Bend® 3.0 mm and 4.8 mm Ruggedized Cables and EZ-Bend Toneable Cables. The toneable cables enable easy above ground locating of buried cables to help avoid cable cuts when other underground systems are installed. These drop cables are installed from the aerial terminal down the pole to the ground, and are then buried to minimize disruption to landscaping, or pulled into existing duct. The cable is then connected into a demarcation box installed at the side of the house, ideally in a location close to the ONT on the inside.

Underground drop cable options include the single-fiber EZ-Bend® 3.0 mm and 4.8 mm Ruggedized Cables and EZ-Bend Toneable Cables. The toneable cables enable easy above ground locating of buried cables to help avoid cable cuts when other underground systems are installed. These drop cables are installed from the aerial terminal down the pole to the ground, and are then buried to minimize disruption to landscaping, or pulled into existing duct. The cable is then connected into a demarcation box installed at the side of the house, ideally in a location close to the ONT on the inside. Seismologists from the California Institute of Technology (Caltech) are using

Seismologists from the California Institute of Technology (Caltech) are using

Multimode transceivers also consume less power than single-mode transceivers, an important consideration especially when assessing the cost of powering and cooling a data center. In a large data center with thousands of links, a multimode solution can provide substantial cost savings, from both a transceiver and power/cooling perspective.

Multimode transceivers also consume less power than single-mode transceivers, an important consideration especially when assessing the cost of powering and cooling a data center. In a large data center with thousands of links, a multimode solution can provide substantial cost savings, from both a transceiver and power/cooling perspective. Beyond the reach of multimode optical fibers, it becomes necessary to use single-mode optical fiber. However, when assessing single-mode optical fibers, be sure to consider newer options. A bend-insensitive, full-spectrum single-mode optical fiber provides more transceiver options, greater bandwidth and is less sensitive to handling of the cables and patch cords than is conventional single-mode optical fiber.

Beyond the reach of multimode optical fibers, it becomes necessary to use single-mode optical fiber. However, when assessing single-mode optical fibers, be sure to consider newer options. A bend-insensitive, full-spectrum single-mode optical fiber provides more transceiver options, greater bandwidth and is less sensitive to handling of the cables and patch cords than is conventional single-mode optical fiber.

Industry standards groups including IEEE (Ethernet), INCITS (Fibre Channel), TIA, ISO/IEC and others continue to include multimode optical fiber as the short reach solution for next generation speeds. This designation reinforces multimode optical fiber’s continued economic advantage for these applications.

Industry standards groups including IEEE (Ethernet), INCITS (Fibre Channel), TIA, ISO/IEC and others continue to include multimode optical fiber as the short reach solution for next generation speeds. This designation reinforces multimode optical fiber’s continued economic advantage for these applications.

Using optical fiber networks, people can access and share information at an amazing level. They can communicate, work and learn from virtually anywhere there’s an Internet connection. For people in

Using optical fiber networks, people can access and share information at an amazing level. They can communicate, work and learn from virtually anywhere there’s an Internet connection. For people in  As everyone uses more bandwidth than ever before, today’s networks require more optical fiber in less space. To help address this need, OFS introduced

As everyone uses more bandwidth than ever before, today’s networks require more optical fiber in less space. To help address this need, OFS introduced